N1 Outdoors: What we believe

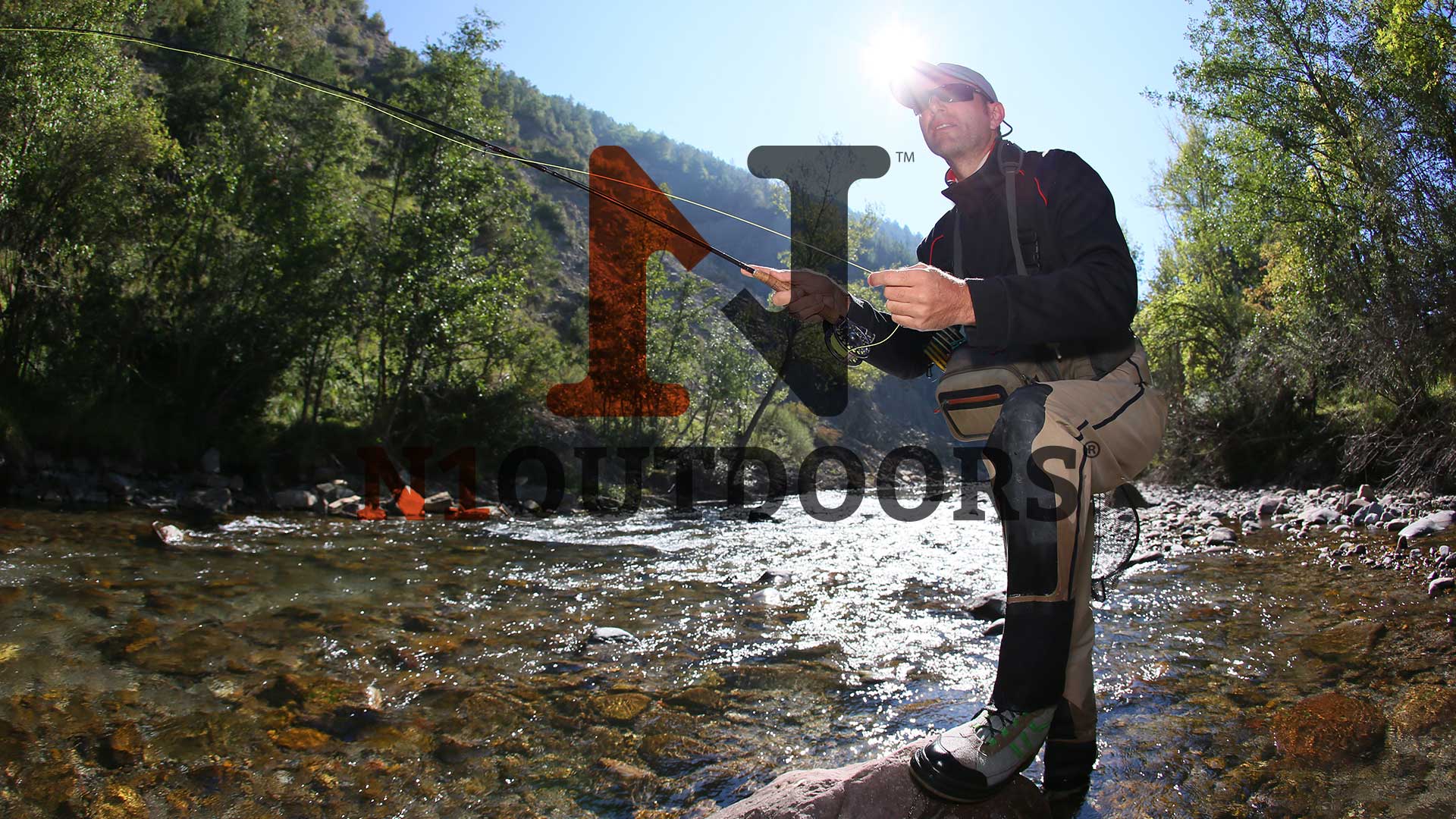

Unforgettable moments in the outdoors are bigger than the kill or the catch… and we call them N1 Moments!

At N1 Outdoors,® we love a trophy fish or animal as much as anyone else. But, we believe that unforgettable moments outdoors are not defined by the size of a trophy, but by the memory made.

We believe you don’t have to be a hunting or fishing professional, a famous person, or a social media superstar to enjoy all that the outdoors has to offer. In fact, we here at N1 are happy to say we are regular folks, just like you, who love spending time outdoors with our friends and families.

We’re not always trying to kill the biggest deer or catch the biggest fish (although we welcome those moments when they come). We are simply taking part in enjoying the creation that God has provided for us, and encouraging others to do the same. And, what a wonderful creation it is!

These outdoor moments shape us, they define us… they are what we live for!

What are N1 Moments?

The great part about the outdoors is that these special moments look different for every individual. For example, when you catch your first fish, take your first animal, or accomplish something outdoors that you’ve never done before, that is a moment that will never be forgotten, regardless of size or score.

But, there are other moments that are memorable, like when the fish didn’t bite, but a lesson was learned in the process.

Maybe your N1 Moment is a memory outdoors with a family member that you will always remember. Moments like these shape us and connect us. We live for these outdoor moments, just like you do.

At our core is a desire to celebrate those unforgettable outdoor moments with friends and family and to create hunting and fishing apparel, as well as products that remind others of those great moments as well.

N1 Moments™ stories are our way of celebrating those outdoor memories and sharing them with others.

Unforgettable moments like this: First deer moments… They are what make the outdoors so special and what we celebrate with you!

Tell N1 Outdoors your story!

So, do you love hunting, fishing and the outdoors? If you do, and have any N1 Moments you would like to submit for consideration to be featured and shared with our audience, please contact us and tell us your story! If your story is chosen, you may be eligible to receive discounts and/or free N1 Outdoors® merchandise!

We want N1 Outdoors to be a place where you can not only get creative and clever hunting and fishing apparel, and watch hunting and fishing videos. But, also a destination for reading about and sharing your hunting stories, fishing stories and outdoor adventures!

And, be sure to check out our blog for hunting and fishing tips, product reviews and information to help you become better at the outdoor activity of your choice.

Where the moments happen, we’ll meet you there! ™

Be sure to follow @N1outdoors on Facebook, Instagram, Twitter, TikTok and YouTube!