Deer meat, otherwise known as venison, is a prized protein for many hunters and outdoor enthusiasts. However, its distinct wild or gamey flavor can be off-putting to some, especially if not prepared correctly.

The good news is that with some proper techniques and practice, you can significantly reduce, or altogether eliminate, the taste that can keep some people from enjoying one of the healthiest meats there is. And, you can turn your venison into a delicious and savory dish!

How To Remove The Wild Or “Gamey” Flavor From Venison

So take a look at some of the methods of removing the gamey, or “wild” taste from venison…

1. Proper Field Dressing and Handling

- The process of removing the internal organs (gutting) and skinning the deer should be done as soon as possible after the kill. The longer these organs remain inside the animal, the higher likelihood of not only unwanted flavor, but also bacteria. So, being able to locate and field dress the animal promptly are very important.

- Make every effort to keep the meat clean and cool during this process. Remove any hair, dirt, and bloodshot areas.

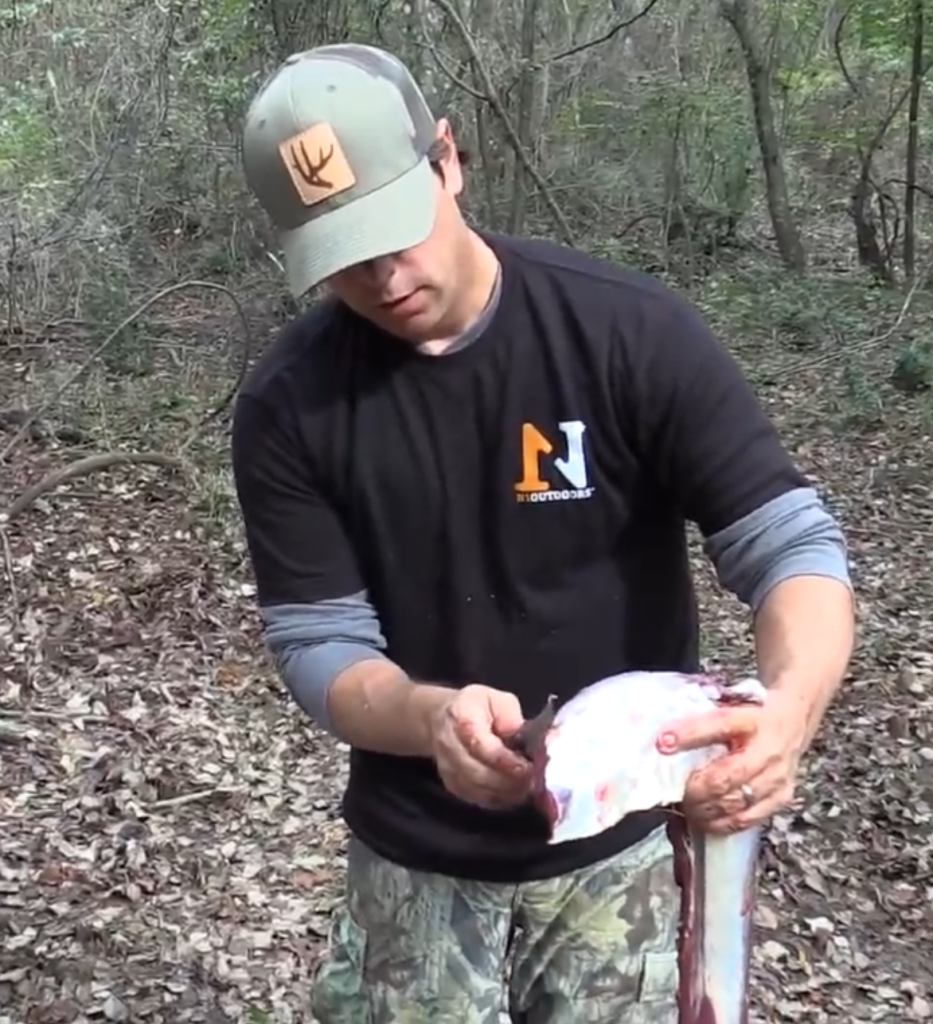

It’s important to keep your deer meat as free from dirt and hair as possible during the field dressing and/or processing.

2. Bleeding and Trimming

- Properly bleeding the deer after the kill can also reduce gamey flavors.

- Placing the quartered and trimmed meat into cooler full of ice will help drain out the blood, which will greatly reduce the gamey flavor. You can allow the meat to sit for days in the ice. However, for best results, empty the bloody water and continue to add fresh ice during this process. If your cooler has a drain on the back, you can leave the drain open to allow the bloody runoff to constantly drain. Just don’t forget to refill the cooler with ice as it melts!

- Trim away any silver skin, connective tissue, and visible fat, as these can contribute to a strong taste that many find unpalatable. Removing the “tallow” or fat from the meat can significantly improve its flavor.

Removing as much silver skin as possible is a great way to reduce the wild flavor that deer can have.

3. Aging the Meat

- Aging venison helps to tenderize the meat and mellow out its flavor.

- You can dry-age venison by hanging it in a cool (34-37°F), well-ventilated area for around 7 to 10 days.

- Alternatively, wet-aging can be done by vacuum-sealing the meat and letting it rest in a refrigerator for 3 to 5 days.

4. Storage and Freezing

- Properly packaging and freezing venison can also help maintain its quality and flavor.

- Vacuum-sealing removes air, reducing the risk of freezer burn and preserving the meat’s taste.

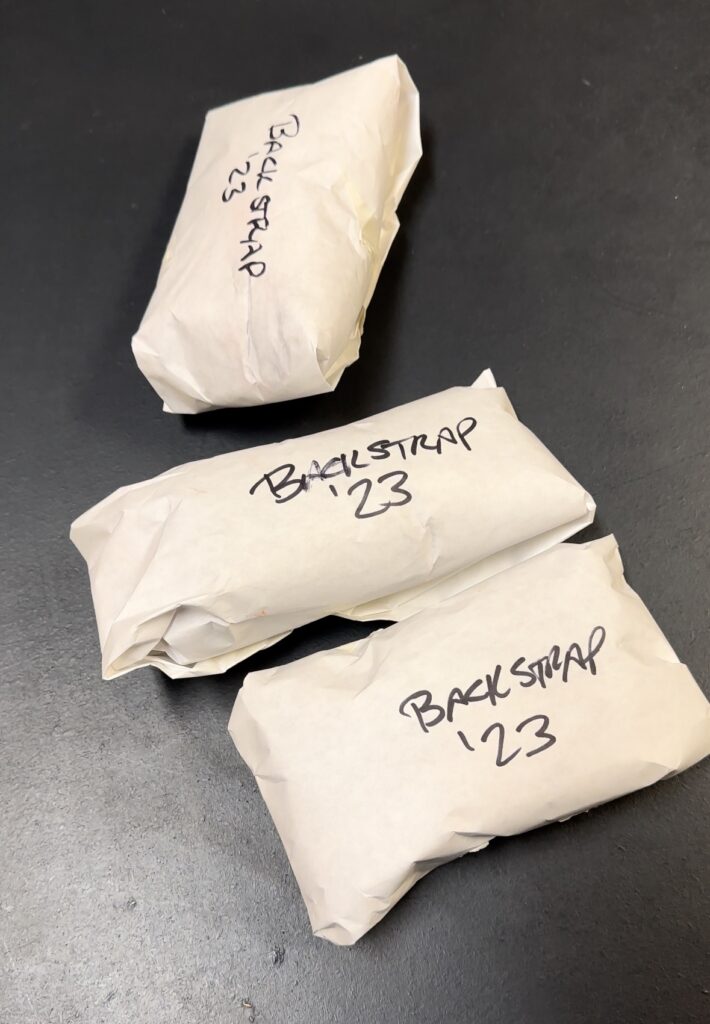

- Use freezer-safe bags or containers, and label with the date to ensure freshness.

Be sure to properly label and date your venison before freezing.

5. Soaking in Milk

- Many hunters swear by soaking venison in milk or buttermilk to remove gaminess.

- The enzymes and lactic acid in the milk help to tenderize and neutralize strong flavors.

- Submerge the meat in milk for several hours or overnight in the refrigerator before cooking.

6. Marinating

- Marinating venison is an effective way to infuse flavor and tenderize the meat.

- Use acidic ingredients like vinegar, citrus juice, or wine to break down the strong flavors.

- Add herbs, spices, and aromatics such as garlic, onion, thyme, rosemary, or juniper berries to enhance the taste.

- Allow the meat to marinate for at least 4 hours or overnight for best results.

7. Use of Seasonings and Ingredients

- Bold seasonings and ingredients can help mask gamey taste.

- Consider using strong flavors such as cumin, chili powder, soy sauce, Worcestershire sauce, or balsamic vinegar.

- Incorporate sweet elements like honey, maple syrup, or fruit preserves to balance out the flavors.

The use of rubs and seasonings can help reduce the gamey flavor that venison can have.

8. Cooking Techniques

- Opt for cooking methods that add moisture and flavor to the meat.

- Slow cooking methods such as braising, stewing, or using a slow cooker can help tenderize and mellow the flavors.

- Grilling or smoking with wood chips like hickory or applewood can add a pleasant smokiness to mask any remaining gamey taste.

- Cooking meats (like a roast) in a croc-pot with vegetables and/or other ingredients, like cream of mushroom soup, can greatly tame a gamey taste.

- Avoid overcooking, as this can make the meat tough and intensify any unwanted flavors.

- Adding ingredients like powdered chicken soup mix to venison burger can not only mask gamey taste, but give the meat a great flavor as well.

9. Mixing with Other Meats

- If the wild taste is still too strong for your liking, consider mixing venison with other meats.

- Ground venison can be combined with pork, beef, or bacon to create flavorful burgers, meatloaf, or sausages.

10. Patience and Experimentation

- Removing the gamey taste from venison can be a process of trial and error.

- Don’t be afraid to experiment with different techniques, marinades, and recipes to find what works best for your palate.

- Patience is key, especially when aging, marinating, or slow cooking the meat.

How to Get the Gamey Taste Out of Deer Burger

While some prefer venison backstraps or steaks, others love deer burger as well.

And, while deer burgers can be a delicious alternative to beef, just like other deer meat, it can have a strong, gamey flavor that might not be appealing to everyone.

So, if you’re looking to tone down that wild taste and make your deer burgers more palatable for you and others that may be new to eating venison, here are some effective strategies to help you achieve a milder flavor:

You likely spent time and effort harvesting your deer. If you’ll spend the same effort after the harvest, you can enjoy one of nature’s healthiest meats as well as great flavor!

1. Trim the Meat Thoroughly

Start by trimming away any visible fat, silver skin, and connective tissue from the deer meat before running it through the grinder. These parts can contribute to that stronger, gamey flavor. (Be sure to use a sharp knife to ensure you remove as much of the unwanted material as possible.)

2. Soak in Milk or Buttermilk

As mentioned above, soaking ground deer meat in milk or buttermilk can help neutralize some of the gamey taste. Simply place the meat in a bowl, cover it with milk or buttermilk, and let it soak in the refrigerator for 2 to 4 hours. Be sure to rinse the meat thoroughly before cooking.

3. Use Spices And Flavoring To Counteract The Wild Taste

Incorporate bold seasonings and spices into your deer burger mix. Ingredients like garlic, onion powder, paprika, cumin, and black pepper can mask and complement the gamey taste. Adding a touch of Worcestershire sauce or soy sauce can also enhance the flavor and add a savory depth to the burgers.

Another effective “seasoning” to help remove the wild taste from deer burger is cream of chicken soup powder. Work and knead it into the deer burger before cooking or grilling and it will give your deer burgers and amazing flavor!

4. Mix with Beef or Pork

Combining deer meat with a fattier meat like beef or pork can also help balance the flavor. You can experiment with different ratios, but mixing 50% deer meat with 50% ground beef or pork typically does a great job of neutralizing an unwanted gamey taste, as the fat content in the additional meat helps mellow out the gamey taste and improves the texture of the burgers.

5. Incorporate Veggies

Mix in finely chopped onions, bell peppers, or even mushrooms into your deer burger mix. These ingredients add moisture and flavor, which can help dilute a gamey taste. They also add texture and make the burgers more flavorful overall. Plus, veggies are healthy!

6. Grill with Flavorful Sauces

Just like with other cuts of venison, if you’re grilling your deer burgers, consider basting them with flavorful sauces or glazes, as mentioned above. A marinade or barbecue sauce can add sweetness and tanginess, which can further mask the gamey flavor and enhance the overall taste of your deer burgers.

7. Don’t Overcook

Since venison doesn’t have much fat, overcooking is a concern, as it can make the meat tough and accentuate its gamey flavor. Cook your deer burgers to medium-rare or medium so you can maintain their juiciness and tenderness.

By following these tips, you can reduce the gamey taste and create delicious, flavorful deer burgers that are sure to please your palate. Enjoy your cooking and the great outdoors!

Final Thoughts On Removing Wild Taste From Venison

By following the above steps, you can transform your deer meat into a delectable and flavorful dish that even those hesitant about the wild taste will enjoy.

So, whether you’re grilling steaks, making a hearty stew, or crafting gourmet burgers, these techniques will help you make the most of your venison and savor every bite.

Happy hunting and bon appétit!