Over the last couple of decades, our lives have changed rapidly. The technological leap humanity has made is truly impressive if you consider how many different once unthinkable technologies are now deeply rooted in our everyday life.

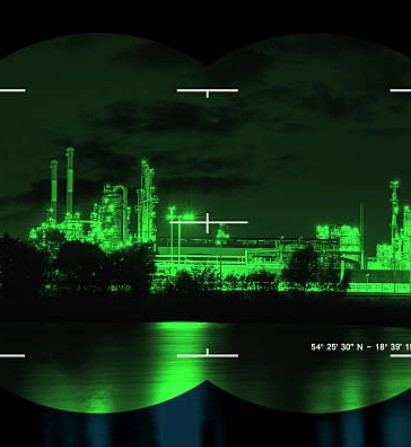

Night vision devices may not be as mainstream yet as smart phones and the internet, but even if you have never had experience using them, you are likely somewhat familiar with them. Video games and movies have firmly rooted in our imagination this magical green glow, which is closely associated with the ability to see in the dark.

But why is that? Why is this glow green, and what technology made it the perfect solution? Well, let’s take a closer look…

Night Vision and The Reasons for Green

The main reason for using that familiar green color in night vision devices is the unique structure of the human eye.

The retina contains photoreceptor cells, some designed to function in low-light conditions (these are called rod cells). Their peculiarity is their increased sensitivity to light, with a wavelength of about 500 nanometers, corresponding to green color.

Due to the presence of rod cells in the retina, the visual system better perceives the different shades of green in the dark. This makes this color an ideal option for displaying images on night optics displays.

Guarantees High Image Clarity

In most cases, night vision optics are used in conditions where they have to capture every photon of light. This is the only way to create a high-quality, valuable image for the user.

Green is less scattered in the atmosphere than red, blue, or any other color, which means the device can receive more source data to create a clear picture on the screen.

As mentioned earlier, human eyes perceive the most shades of green. So, this also helps to create a visually brighter and clearer image, in which the user can see all the small details.

Less Eye Strain

The compatibility of human vision with the color green makes it the safest option. It creates strain on the eyes than red, blue, yellow, orange, and other colors. This protects the human visual system from functioning at the limit of its capabilities and reduces the likelihood of eye pain and other various problems like lacrimation, decreased visual acuity, etc.

In conditions of insufficient light, a person perceives green better. This allows the reduction of the load and the prevention of rapid eye fatigue. This is especially important during prolonged use of night optics, when there is may be no opportunity to take a short break. In such conditions, a green image allows for comfortable observation and searching for something in the dark.

If you were to use another color, discomfort would increase, and prolonged use of night optics would be a potentially unsafe activity.

T-Shirts For Deer Hunters From N1 Outdoors

-

N1 Outdoors® HUNT. Tee (Various Colors)

$24.99 – $28.99 -

N1 Outdoors® Sunrise In Tineville™ Tee

$28.99 – $32.99 -

N1 Outdoors® “USA Antler” Tee

$24.99 – $28.99

Presence of phosphor screens in the design

Another reason for using green was the presence of a phosphor screen in the design of many devices. This screen It is an integral part of night optics, which operates on the principle of light amplification.

Phosphor screens have long been indispensable design elements of night vision equipment. Because of this, green has been considered the primary color in night optics for many years, and many users have become accustomed to it. Therefore, even with alternative options, green has remained the standard color.

In the design of NV glasses, binoculars, monoculars and sights, the phosphor screen caters to accelerated electrons. When they hit it, a flash of light with a wavelength of 500-550 nanometers occurs. This flash of light corresponds to the green color that users see.

Traditionally Green

Because green has been the standard color for night optics for years, some manufacturers continue to adhere to produce many models with that familiar glow.

Now, that doesn’t mean that manufacturers have stopped searching for alternative options. Nevertheless, green is still the most popular and continues to drive the demand.

Options for using green night vision

Because green is the most popular night vision color, the slaes of night vision goggles, thermal monoculars, and other night vision equipment utilizing this color allow for higher manufacturer revenue.

So, in essence, the color green produces more “green” for the manufacturers!

Because green allows for the most prolonged usage with the least amount of eye strain, it is indispensable for use in the military, law enforcement, security, rescue, and dozens of other professions.. And, as previously noted, the green also helps the user to see small details, even in images of lower quality.

In everyday life, green night vision is also used in 24-hour video surveillance cameras. Its use allows for quick identification of strangers, and detection of various problems, like fires. It also great for enjoying moonlight entertainment, and the observation and even hunting of predators.

What other types of night vision are there?

Thanks to the development of technology, alternative night vision colors are available, and each is effective in particular scenarios.

Black and White Night Vision

The so-called white phosphor night vision devices are gaining popularity most quickly. They allow you to get a black and white image on the display, which some people may perceive better than green. Its main advantage is its natural look. The image looks similar to that of old films, which is more familiar than a picture in green tones. Also, the black and white version provides excellent detail.

Multi-Color Night Vision

Multi-color night vision (not to be confused with thermal) is another popular way to get good visibility in the dark. It is used exclusively in modern optics models, which are often very expensive. In these devices, different shades are obtained through special image processing algorithms.

Green Still Great In Night Vision

A green image on the screen of night optics has been the standard for years, and has come to be known mainstream as “the night vision color.”

Even though modern devices will now allow you to see a black and white or even multi-color image, green still rules the day and will be a favorite of millions of night vision users for years to come.