You can’t have too many broadhead tests. So, I’ve got another broadhead that I tested that I want to share with you… it’s a classic head with a twist. It’s the Muzzy Trocar TI 100 grain.

For all the performance testing of the Muzzy Trocar TI 100, I used my Elite Era compound bow. But, for the accuracy testing, I’m using this Killer Instinct SWAT X1 Crossbow, because it eliminates so much human error.

The Muzzy Trocar Ti 100 Grain Broadhead Up Close

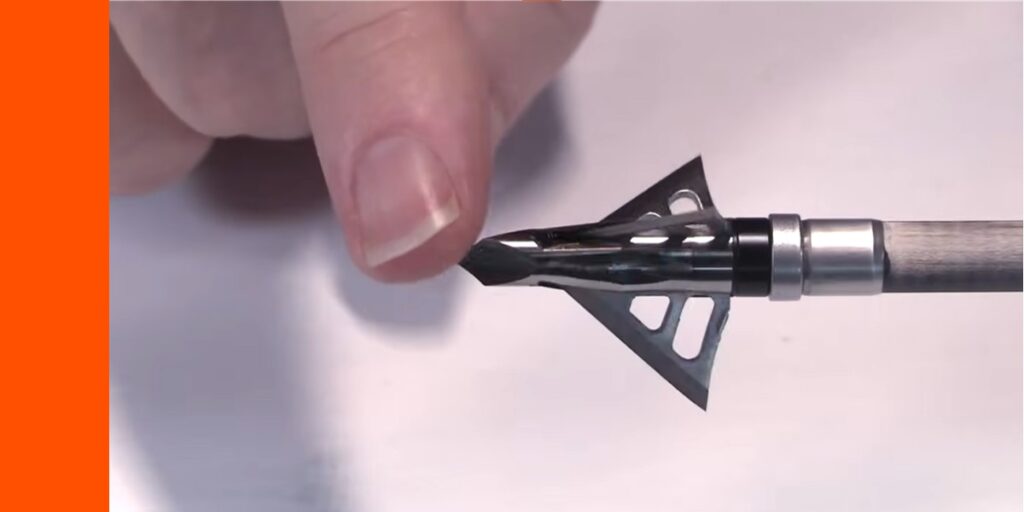

Here’s a good look at this head. It’s just a nice, proven design. It has a lot of cool features. I’ll start with the materials.

It’s got a titanium ferrule, which is lighter than most steel and allows for putting weight into some other parts, even though this is just a 100-grain head.

Bowhunting Shirts from N1 Outdoors®

-

Just Pass’N Through™ Tee (featuring Magnus Black Hornet Ser-Razor Broadhead)

$15.00 -

Just Pass’N Through™ Tee featuring Iron Will (Various Colors)

Price range: $24.99 through $28.99 -

N1 Outdoors® Bareback Bowhunter™ Tee

Price range: $28.99 through $32.99

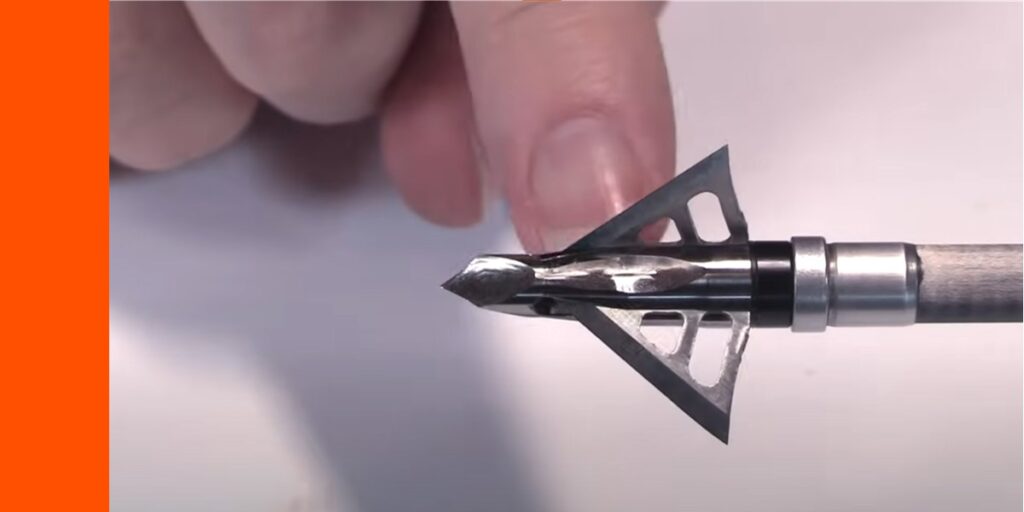

It also has a nice chiseled tip, which I really like.

And it has a type of threaded retention collar, if you will (I believe it’s aluminum).

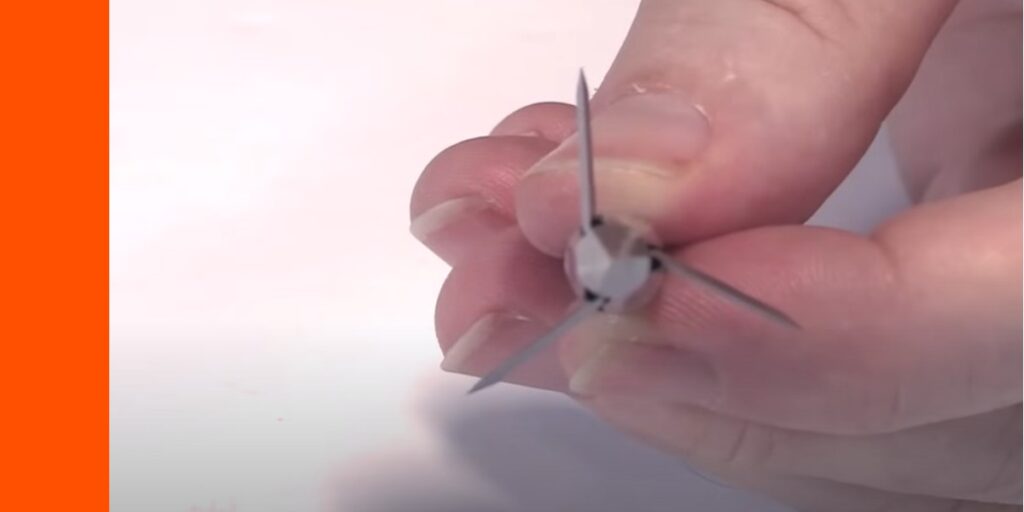

The blades are, of course, stainless steel and a stout 0.0408″ thick, so relatively thick blades there. The cutting diameter is 1.25″, even in this 100-grain model. So, the total cut is 1.875″.

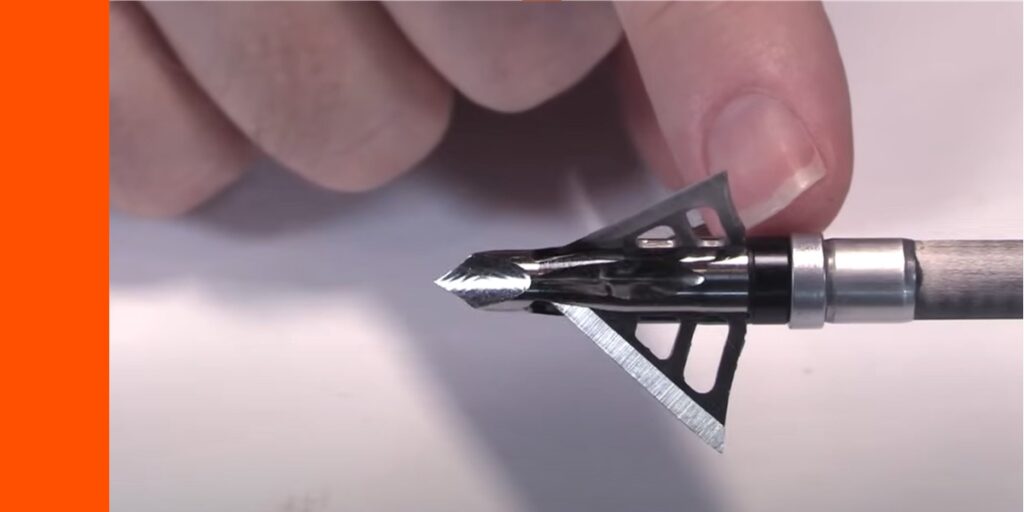

Another cool thing about this head is that the blades are offset, meaning they don’t all just point toward the center of the ferrule. They’re a little offset. What that does is that it creates a really nice rotation, both in flight, as well as within a medium or animal, to make an even more wicked wound channel.

Another neat thing is that you have a choice of whether you want the blades to rotate left or right by changing the offset. Now, you want to make sure, just like with a single bevel head, (though this is a double bevel head), that the blade offset matches your fletching. So, for example, if you have a right helical or right offset fletching, then you’d want to be sure you put the blades in the right rotation position. And, vice-versa if you have a left helical or left offset fletching.

For resharpening, I would use the Stay Sharp Guide Replaceable Blade Kit. That works really well with broadheads like this.

I was really eager to put this head to the test and see how it performed. So, let’s see how it fared in the various tests…

Flight Forgiveness Test

For the flight forgiveness test, I shot one field point and then one broadhead, at 30 yards, out of a Killer Instinct SWAT X1 Crossbow, with a 675 grain Bishop Bolt, at 300 feet per second.

The Trocar got the 9-ring.

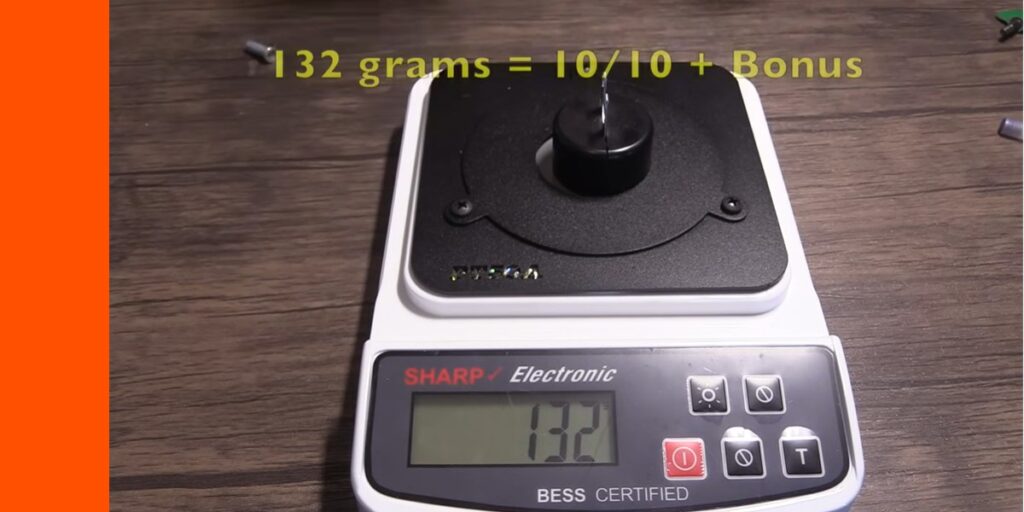

Edge Test #1: Initial Sharpness Test

In this test, I checked how many grams of force it took to to cut copolymer wire.

It took 132 grams of force to cut through the wire, which is a 10 on a 10-point scale, plus a bonus for going under the threshold of 200.

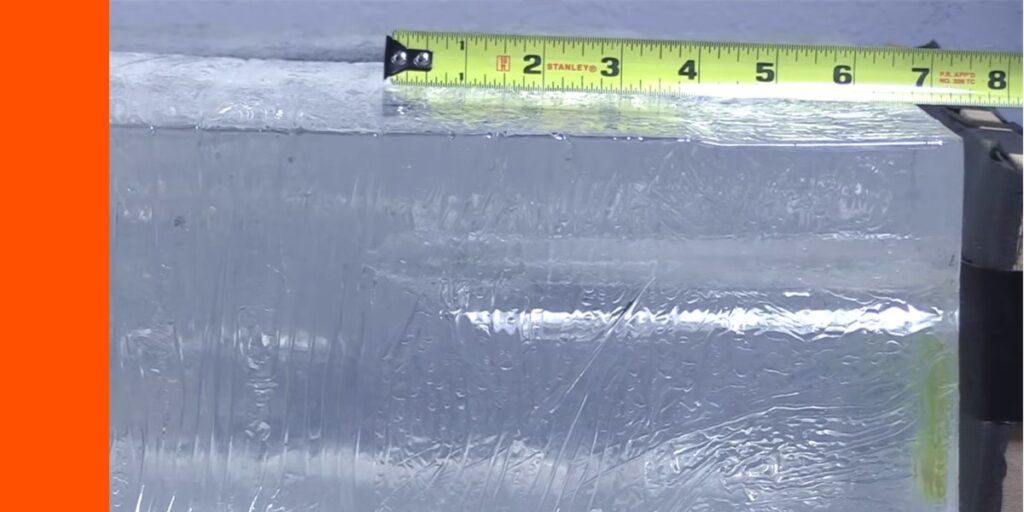

Penetration Test #1: Ballistic Gel and MDF

In this first penetration test, I , shot the head into ballistic gel, fronted by 2/3″ Rubber Foam Mat and 1/2″ 1/2″ MDF.

It penetrated 8-1/2″.

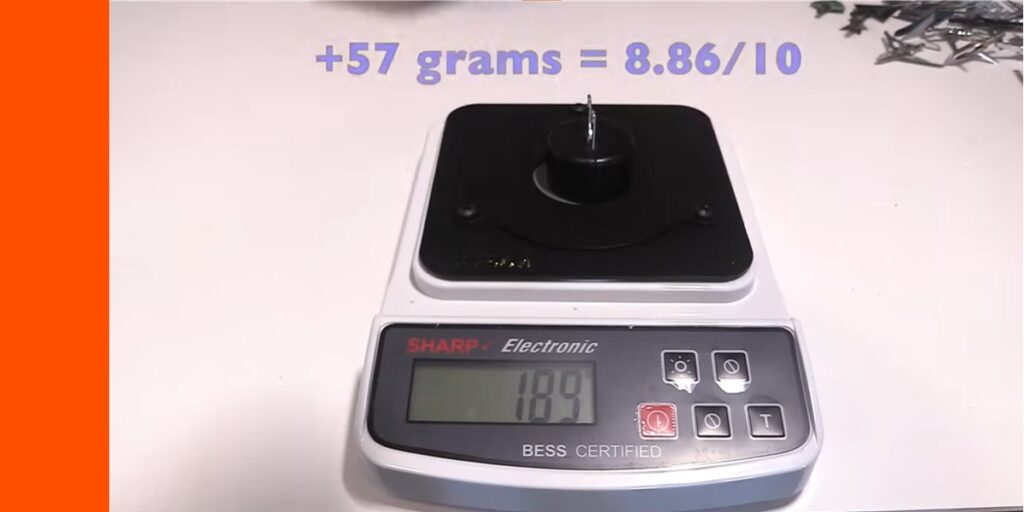

Edge Test #2: Edge Retention

In this test, I checked the sharpness of the blades after penetration test #1.

It took an additional 57 grams of force to cut through the wire, which is an 8.86 on a 10-point scale.

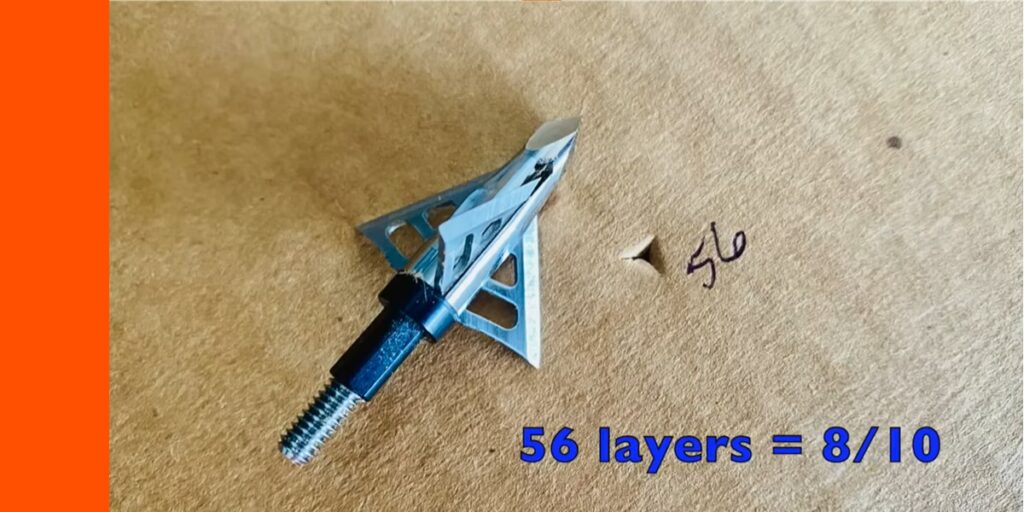

Penetration Test #2: Layered Cardboard

It penetrated through 56 layers, which is an 8 on a 10-point scale.

Durability Test #1: 3 shots Into 1/2″ MDF

The head is in perfect shape after the 3 shots through the MDF.

Durability Test #2: Two Shots Into 22 Gauge Steel Plate

And here is the Muzzy Trocar Ti after just one shot through the steel plate. I didn’t shoot it a second time, because on the very first shot, all the blades came out. And, if you look closely at the base of the ferrule, you can see where the blades have made a little divot back into that retention collar that I feared was a weak point. And, indeed it was, because it backed up just enough to then fall out of the little locking mechanism at the top. So, that’s unfortunate. Now, it did make a nice hole, that you can see here. You can also see that rotation from the offset blades. But, it just lacked the durability to stay together.

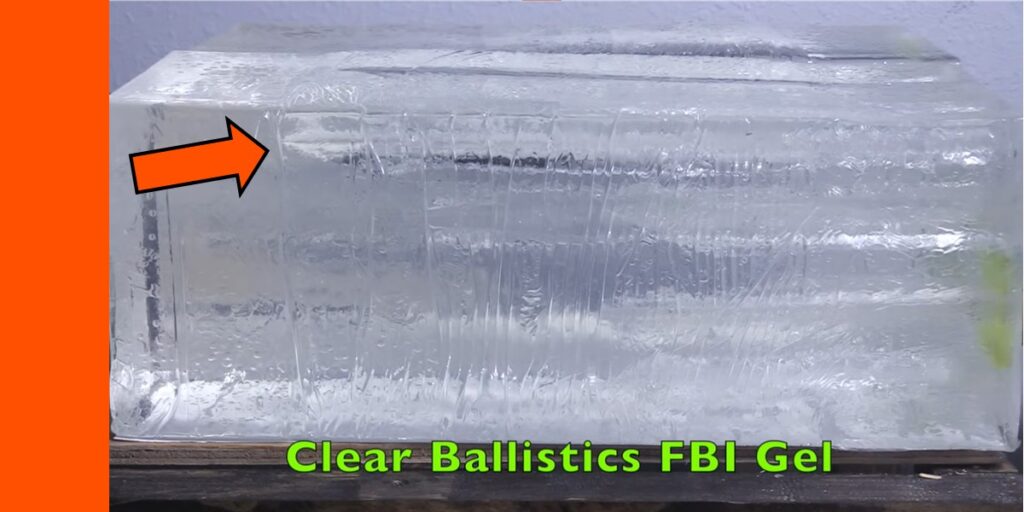

Retention Test: Clear Ballistics FBI Gel

It rotated 90 degrees at 12″. Really good rotation.

Durability Test #3: One Shot At Cinder Block

Here is the head after all the durability testing. You saw that the blades all fell out in a steel plate, because this retention collar is just so soft. The blades backed in and cut into it, and then there was nothing to hold them in place. But, I went ahead and shot it into the cinder block like this, and you can see that the ferrule held up well.

Arrow Wraps from N1 Outdoors®!

-

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Angry Arrow™

Price range: $18.99 through $27.99 -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Just Pass’N Through™

Price range: $18.99 through $27.99 -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Camo Fade (Various)

Price range: $18.99 through $27.99

Final Thoughts On Muzzy Trocar Ti Broadhead

So what do you think about the Muzzy Trocar Ti in 100 grains?

Man, there’s a lot of great strengths to this broadhead. It performed well in a lot of different areas, including cut size, blades, and the ability to change the rotation of the blades. Additionally, I love that rotation of the offset blades, the ferrule, and chiseled tip.

But man, I’m concerned about that retention system. When all the blades came out, that was a shocker to me.

Maybe I got a bad batch or something, but that’s just something to keep in mind before you use them. I know shooting them in the steel plate, that’s a pretty big shock, but still, most fixed blade heads breeze through that like butter.

I hope you enjoyed this review. Be sure to check out all the other broadhead reviews.