I always love it when new broadheads come out. And, there was a new one from a company I had never heard of… Exact Archery.

I reached out to them and they sent me a pack. They sure do look cool and I was eager to put them to the test!

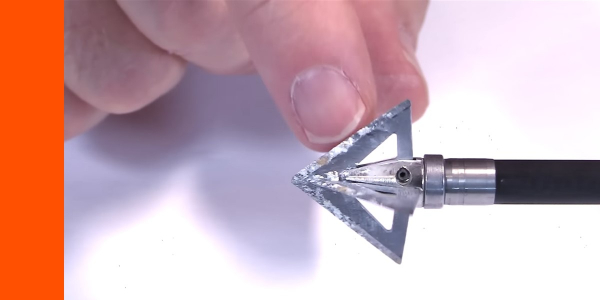

The Exact Archery Broadheads Up Close

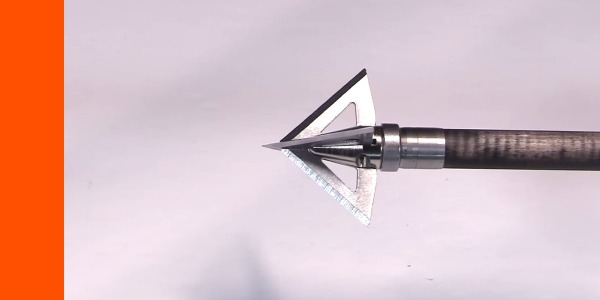

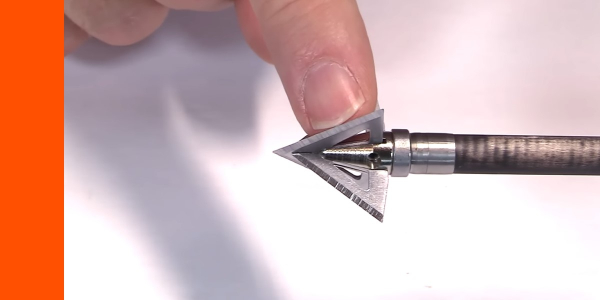

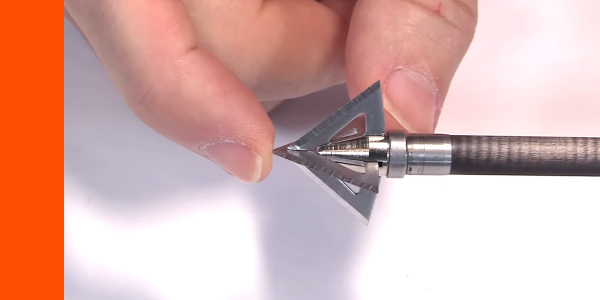

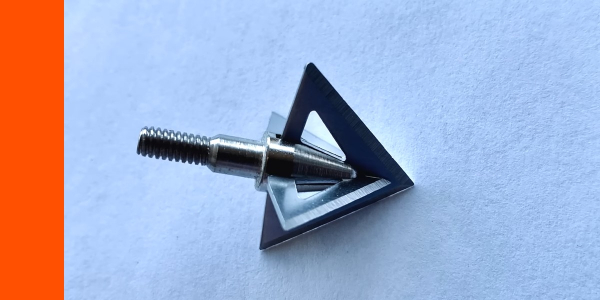

Let’s zoom on in and take a look at the Exact Archery Broadheads…

Here’s a good look of the Exact Archery Broadhead here. This is 4-blade, as you can tell and it’s the 100-grain model. Now, I will note that just for a few bucks, you can pick up some of these little washers and they just slide on to the back; and, they don’t make it any longer. They don’t take up any of the threading because that little slot just slides over the blades and makes it a 125-grain. So, you have the same basic broadhead in 100 grains or 125 grains. Now, it does add a little bit of a lip that’s going to have a little bit of resistance to some mediums as it impacts, but not very much. So, it’s nice that you have some modularity there between 100 and 125-grain.

The Exact Archery broadhead is all steel. The ferrule, and the blades are both stainless steel. Each of the blades are 0.040″ thick, so these are some of the thicker blades on the market for a replaceable blade broadhead.

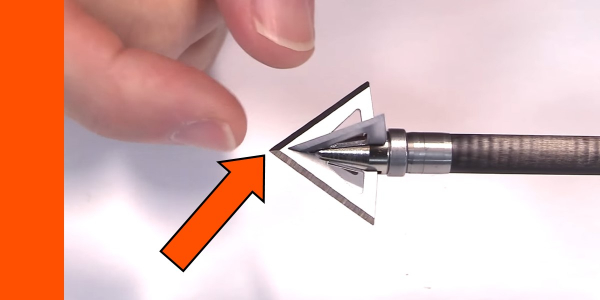

The cutting diameter in each direction is 1-1/8″. So the total cut is 2-1/4″. That’s no slouch! It’s like a Slick Trick Magnum head.

You’ll notice that there’s no tip other than this blade. It’s a true cut on contact tip.

Notice that it has an an extremely short overall profile.

By my measurements, the head measurement comes out to 0.85″ long. So, that’s one of the shortest broadheads that I know of. But, even so, you’re getting a decent size cut. So, I would imagine it’s going to minimize surface area and maximize flight forgiveness and penetration.

I wondered a little bit about the durability on a hard impact with this cut on contact blade since it doesn’t have a chiseled tip (more on that below). I thought the ferrule would probably be pretty durable because it’s so short.

-

N1 Outdoors® Whitetail Sugar Skull Tee (Black/Columbia Blue)

$26.99 – $29.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Just Pass’N Through™ Bowhunting Tee

$24.99 – $28.99 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

N1 Outdoors® N1 Moments™ Licking Branch Buck SS Tee

$5.00 Select options This product has multiple variants. The options may be chosen on the product page

Exact Archery Broadheads Testing

It’s not very expensive broadhead, but seems really well-constructed. I was eager to see how it performed!

In the following tests, I used my Bowtech CP28 set at 72 pounds. I’m using Bishop FOC King Arrows for most of the shots and Bishop FAD Eliminators for the shots into the concrete, because they can handle it like no other arrow that I’ve ever tested.

Flight Forgiveness Test

For the flight forgiveness test, shot 1 field point and then 1 broadhead at a distance of 40 yards. It had excellent flight!

Initial Sharpness Test

It took 200 grams of force to cut through the wire. That’s a 10 on a 10-point scale!

-

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Camo Fade (Various)

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Bowhunt Oh Yeah™

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Transparent Arrow Wraps (Non-Reflective)

$16.99 – $25.99 Select options This product has multiple variants. The options may be chosen on the product page

Penetration Test 1 (2/3″ rubber mat, 1/2″ MDF, FBI Gel)

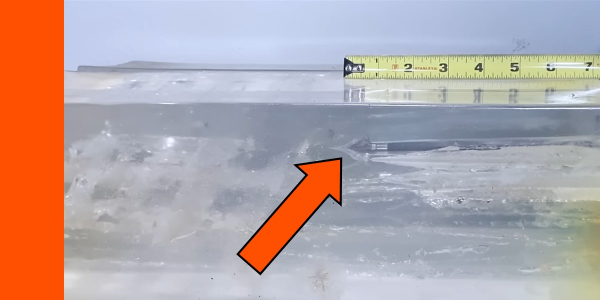

When shot into the ballistic gel fronted by a 2/3″ rubber mat and 1/2 MDF, It penetrated 9 inches (MDF and rubber mat not shown in this pic, but it was 9 total inches).

Edge Retention Test (sharpness after Penetration Test 1)

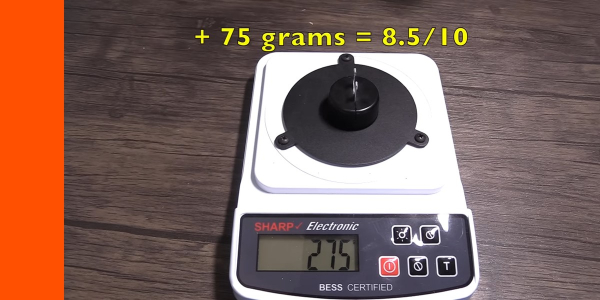

It took an extra 75 grams of force to cut through the wire, which is an 8.5 on a 10-point scale.

Penetration Test 2 (layered cardboard)

The Exact archery head penetrated through 64 layers of cardboard.

Angled Shot Test (1/4″ MDF/Carpet):

It had no problem in the angled shot test.

Durability Test (1/2″ MDF max 3 shots):

It was in excellent condition after going through the MDF three times.

Durability Test (22 gauge steel plate max 2 shots):

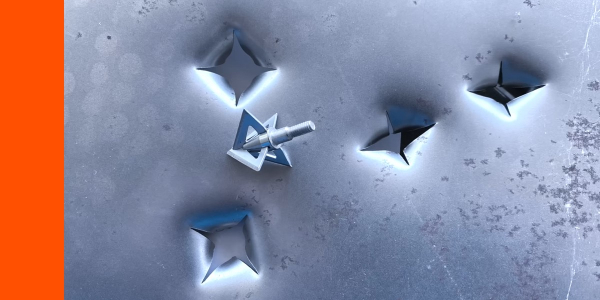

Check out these holes in the steel plate (left). Man, these are really nice holes. They are like square chunks. If you compare it to these other holes that were made by a broadhead I tested right before this (right side), you can really see the difference (both are 4-blade heads). But man, what a difference in the wound channel it opens up. And the head is in just fantastic shape. There’s a little tiny chip that was taken off the very tip. You can’t even make it out on this picture. But that was just really minor, and otherwise, the head stayed in excellent shape.

#ad

Concrete Test

So here is the Exact Archery broadhead after all the durability tests. I did not expect it to hold together as well as it did (through the MDF 3 times, the steel plate 2 times, and then into the concrete). Man, it stuck so deeply into the concrete!

As for durability, after the concrete test, it had a slight bit of wobble to it. And, the tip got a little bit dinged up in the concrete, but it showed really impressive durability for this type of design.

#ad

Final Thoughts On The Exact Archery Broadhead

So what do you think?

Man, the Exact Archery broadhead really, really surprised and impressed me!

When I first saw it, and looked at the price point (7 bucks a head), I was thinking, “OK, I’ve seen designs like this. The blades are probably going to separate on hard impact. Maybe they’re going to break. Maybe they’re going to roll over.”

I was wrong!

The Exact Archery broadhead scored 10 out of 10 golden arrows… wow!

This head is impressive in every area. It flew super well. It penetrated really well in every medium. It held together well in MDF, the steel plate, buried into the concrete… wow! And, this is just the 100-grain version. You add that extra washer down there at the bottom, to get up to 125, it might do even more!

And, here’s the thing. This head got a score 10 golden arrows! There are not many heads that get 10 golden arrows, but this one did. And it’s 7 bucks a pop. Man, that’s really impressive!

So hey, Exact Archery, you’re doing something right. Welcome to the ballgame. I look forward to seeing more stuff that you come out with in the future!