After receiving many requests to test the Muzzy Trocar HBX broadheads, I finally got to do just that!

This head has been around for awhile. It’s a 100-grain, fixed and mechanical blade broadhead combination; a “hybrid” broadhead.

For these tests, I used my Bowtech CP28 set at 72 pounds. I used Bishop FOC King Arrows for most of the shots, but for the really the hard impact ones, I used the Bishop FAD Eliminators.

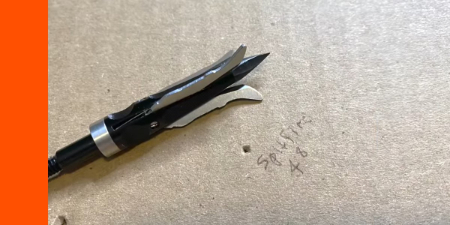

The Muzzy Trocar HBX Up Close

So, let’s zoom on in here, go through some of the design features and specifications of the Muzzy Trocar HBX…

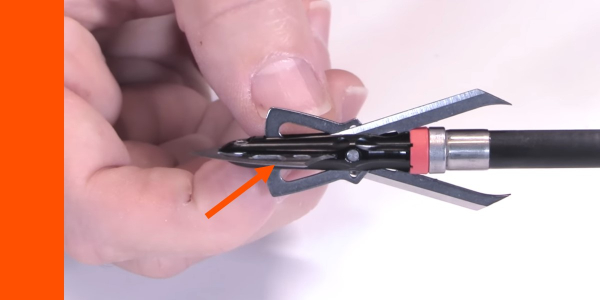

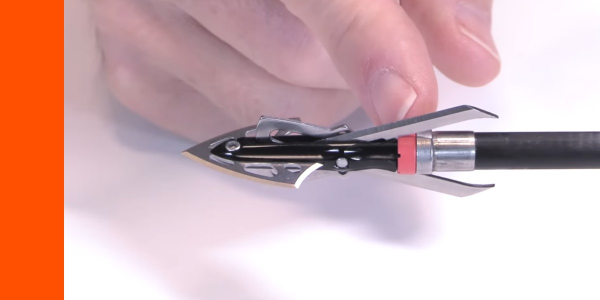

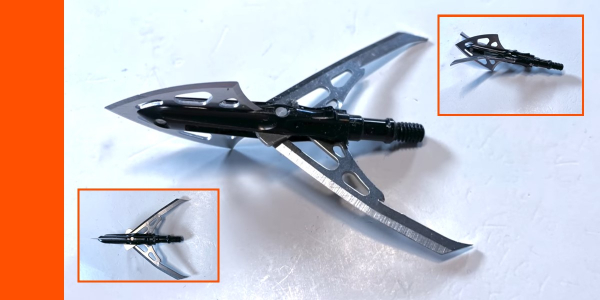

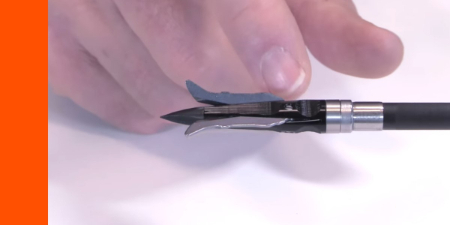

Here’s a good look at the Trocar HBX hybrid broadhead. It’s called a “hybrid” because you have a fixed blade, which is actually two separate blades that slide into ferrule with a one inch cutting diameter, and it doesn’t open or close, it’s just fixed.

There’s also a mechanical blade that in the closed position is 9/10 of an inch, and then the open position, it expands to 1 and 5/8″ when fully opened. The cut is 2 and 5/8″ when combining the cut of the mechanical blades with the the fixed blades.

The bladed are 0.35” thick, and the the ferrule, chiseled tip, and the blades are all stainless steel.

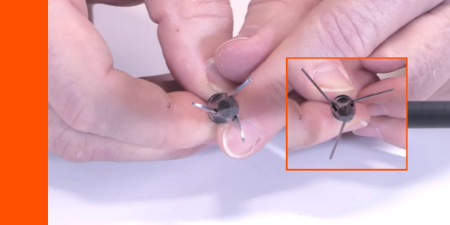

The opening is a rear-deploying, gator style, opening system to where it’s the pressure on these two blunt blades that force these blades open.

Now, I will say it takes a lot of pressure, even just to pull the blades apart. And, they don’t lock open, but they remain open when there’s a pressure on that little gator end, that causes them to open.

So, I was a little concerned about how that opening was going to work and if it would stay open. But, even if it didn’t get the full cut, it would still be a lot of cut.

Muzzy Trocar HBX Testing

So, I was super eager to put this head to the test and see how it performed.

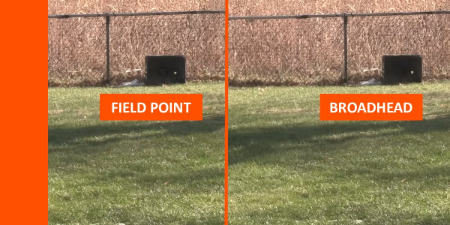

Flight Forgiveness Test

For the flight forgiveness test, I shot 1 field point and then 1 broadhead at 30 yards.

The broadhead flew very true to the field point in the flight forgiveness test.

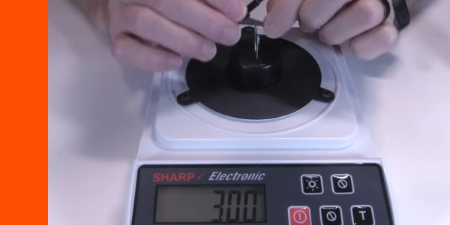

Initial Sharpness Test

I tested the “out of the box” sharpness of the head (the lower the number indicates that it takes less pressure to cut the wire, indicating a sharper blade).

The mechanical blade registered 200.

The fixed blade registered 300.

Penetration Test 1 (2/3″ Rubber mat, 1/2″ MDF, FBI Gel)

I shot the head into ballistic gel that was fronted with a 2/3″ rubber mat and 1/2″ MDF.

The Muzzy Trocar HBX penetrated 8.25″ into he ballistic gel. But, I do want to note that while the blades opened very well on impact, (they open until almost their full cutting diameter even in the rubber foam mat), they quickly started to close as soon as they hit the gel and they remain closed throughout the entire penetration. So, it really wasn’t cutting its full tissue throughout that 8-1/4″, and that’s not uncommon with gator blades. It usually happens in gel with gator blades, especially with ones that don’t lock. Now, would that happen in animal? I’m not really sure. But, I want to make note of it because it does give kind of false reading in the penetration.

Edge Retention Test (Sharpness Test After Penetration Test 1):

I tested the sharpness again after the first penetration test.

Mech Blade: 225.

Fixed Blade: 325.

Penetration Test 2 (layered cardboard):

The head penetrated through 48 layers of cardboard.

Angled Shot Test (1/4″ MDF/Carpet):

I shot the head into angled MDF.

-

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Paint The Earth™

Price range: $18.99 through $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Time Traveler™

Price range: $18.99 through $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Nock Down Power™

Price range: $18.99 through $27.99 Select options This product has multiple variants. The options may be chosen on the product page

“Get N-Tune” with our arrow wraps!

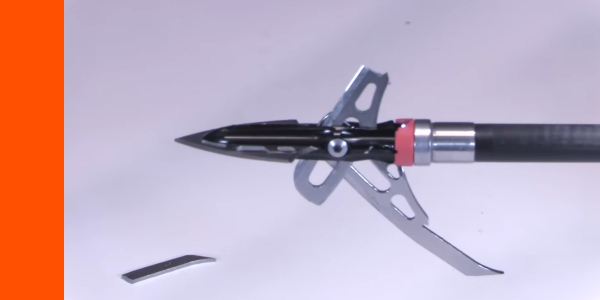

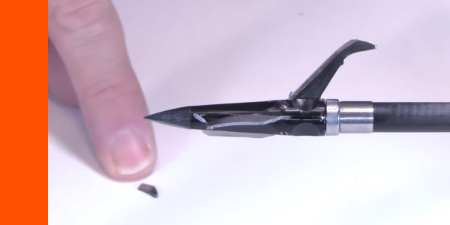

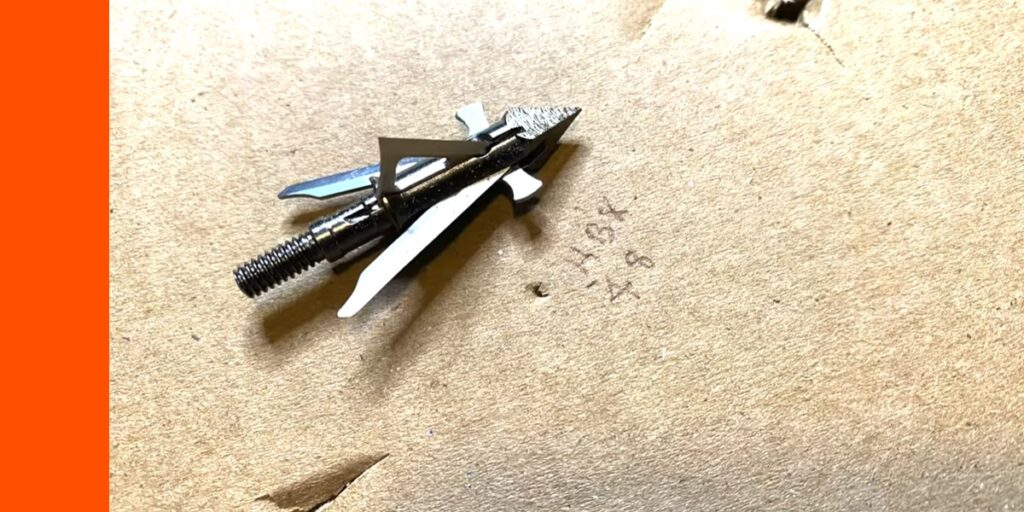

Durability Test (1/2″ MDF max 3 shots):

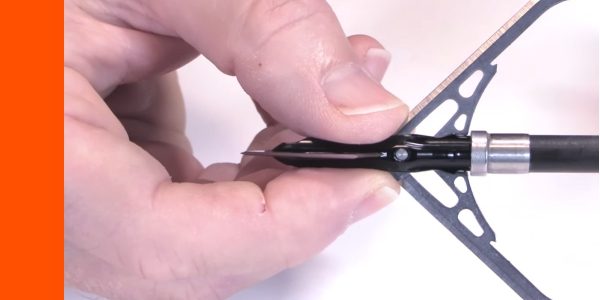

Man, this test was a shocker. On the first shot through the MDF, it broke a blade. I can’t remember the last time I’ve seen something like that happen, and I certainly wasn’t expecting it to happen with this Muzzy.

But, it did.

In the first shot into the MDF, the blade just broke right off and embedded somewhere in my target, and that’s really unfortunate. So, I was not able to shoot it into a steel metal plate, which is typically my next test. I also couldn’t shoot it into the concrete block, which is usually my last test.

Final Thoughts On The Muzzy Trocar HBX

So, what do you think of the Trocar HBX?

It has its strengths. For example, it flew very well, has a really good size cut, and a really tough chiseled tip. I also love the all-steel construction.

I was not, however, very impressed with the durability. Actually, it’s lack of durability surprised me.

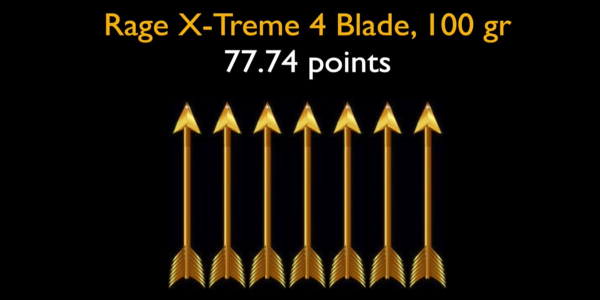

The Muzzy Trocar HBX scored 74.10 out of a possible 100 points, giving it a Lusk Grade of 7 golden arrows.

I know these blades are pretty thin, narrow and not very supported, but I expected a little bit better there in durability.

Now, I’m sure it can get the job done in most situations. In fact, I’m sure many of you have used it very successfully in the field.

So, check out the score sheet and see it’s score out of a possible 100 and decide if it’s a good fit for your quiver.