“The world’s toughest broadhead.”

That’s a pretty bold claim, and I set out to see if it was true.

But, even before I shot the Bishop Holy Trinity 200-grain broadhead, I thought that it could actually be true.

Why?

Well, because there are four basic ways you can determine how strong a broadhead is before you even shoot it into anything.

So, before we look at what I found in the testing of the Bishop Holy Trinity head, let’s briefly look at those four indicators below.

Is the Bishop Holy Trinity the world’s toughest broadhead? Well, I was going to find out for myself! Keep reading to find out what I learned…

Four ways to determine broadhead strength

The four ways to determine the strength of a broadhead are as follows:

Steel Quality

The first indicator of a broadhead’s strength is the quality of the steel itself.

What kind of steel is it?

To simply say something is all steel is nice, but there is a wide range of steel types, so the quality of the steel is important.

Rockwell Hardness

The second indicator of broadhead strength is Rockwell hardness.

How is the broadhead hardened and to and to what degree is it hardened?

To increase sales, some broadhead manufacturers will state that the head has been hardened to “x” degree of Rockwell hardness. But, if it’s the wrong kind of steel to handle that hardness, it’s just going to fracture and even edge chatter and shatter upon impact, which a lot of heads do.

So, this makes Rockwell hardness important, but also how the hardness is handled by the material.

-

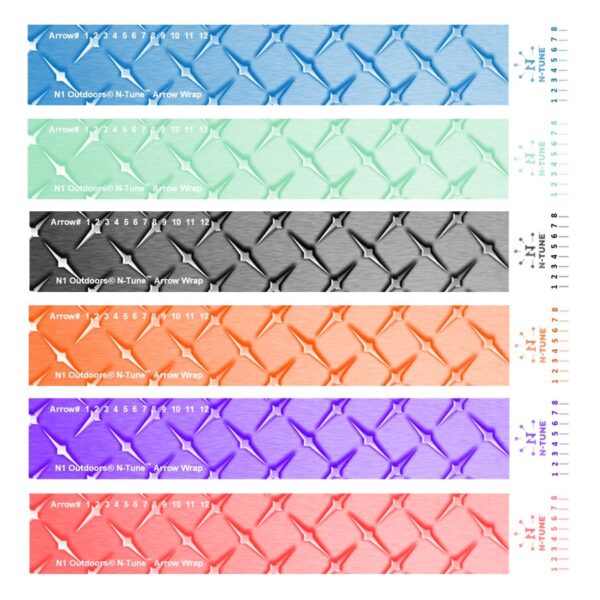

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Diamond Plate (Various)

Price range: $18.99 through $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

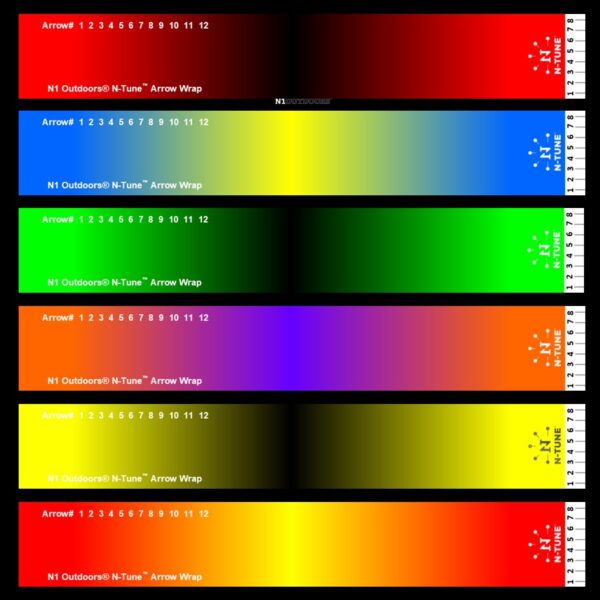

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Dual Fade (Various)

Price range: $18.99 through $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Flatliner™

Price range: $18.99 through $27.99 Select options This product has multiple variants. The options may be chosen on the product page

I did some in-depth testing on the Holy Trinity, as well as the rest of the Bishop line of heads… Keep reading!

Steel Composition

The third indicator of broadhead toughness is the composition of the steel.

In other words, how is the steel put together?

For example, is the broadhead made from multiple pieces of steel that are welded together? A lot of broadhead manufacturers do that.

Is the head made up of multiple pieces that are held together by a set screw or two? Many companies go that route.

It could be a single piece head that’s metal injection-molded (MIM). Or, it could a single piece that’s CNC machined, which is by far the toughest. In that case, it would be machined out of a single chunk of bar steel.

Geometric Design

The fourth measure of toughness for a broadhead is geometric design.

How stout is the head? How thick are the blades? How supported is the tip of the head?

All these components of geometric design make a difference in the strength of the head.

Why Bishop Holy Trinity Could Be The World’s Toughest Broadhead

So, knowing the four factors covered above in determining a broadhead’s toughness, here’s why I thought the Bishop Holy Trinity could be the toughest broadhead on earth.

Steel Quality of Bishop Holy Trinity

The first reason I say it could be the world’s toughest broadhead is, first, they used a proprietary S7 tool steel.

S7 tool steel is one of the toughest steels there is. It’s incredibly tough. And this one particularly, the tool steel that Bishop uses, has a Charpy resistance impact in the 90’s (Charpy V-notch testing is a way to resist the impact of something to that steel).

To put that in perspective, it’s more than four times more resistant to impact than stainless steel.

Rockwell Hardness of the Holy Trinity

The steel of the Bishop Holy Trinity is then brought to a Rockwell hardness of 58, which is pretty amazing.

They can do that because of the type of steel that it is.

Steel Composition of the Bishop Holy Trinity

Then, the Holy Trinity head is CNC-machined, which is by far the strongest way a head can be designed. It’s very expensive to do that, especially out of that quality of S7 tool steel.

It’s really expensive but it’s also really tough.

Geometric Design of Holy Trinity

Fourthly, the geometric design of the Holy Trinity (the 200-grain specifically) is that it has a really short geometric design.

The Holy Trinity’s geometric design is shorter than others on the market like VPA.

VPA are great heads. But, the Holy Trinity is just a shorter, stouter design. So, it’s going to fly a little bit better than most other heads like that because it has a lot of surface area and it’s going to hold up better to impact because of that stouter design.

But, then the blades on this head specifically are 0.070 inch thick which is a really thick blade, one of the thickest on the market.

And then the 200 grain, unlike the 125 grain model, has an extra support that’s kind of like a blade in and of itself. It’s like a triangular wedge-type blade that is really thick.

For the thickness of the Trinity, it’s the sharpest it can get. It’s brought to an edge that’s going to cut through bone really well if something doesn’t get caught by the primary leading blades. It’s not a 6-blade head, but it’s almost like a 6-blade because it has the extra pieces in there that will make it more resistant to coming out of an animal as well.

So with everything about this, the type of steel, the hardness, the CNC machining, and the geometric design, this head certainly has the potential to be the “world’s toughest broadhead.”

I do a lot of research on broadheads. I don’t know anything that’s going to come even close to it except Bishop’s 41L40, their Bridgeport head that’s the same. It’s just a little bit lesser tier type of tool steel, but still way above most other tool steels that other heads on the market have.

-

N1 Outdoors® Thwack’Em™ Bowhunting Tee

Price range: $24.99 through $30.99 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

N1 Outdoors® Licking Branch Buck LS Tee

$19.00 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

N1 Outdoors® N1 Moments™ Licking Branch Buck SS Tee

$5.00 Select options This product has multiple variants. The options may be chosen on the product page

>> Check out all the N1 hunting shirts HERE!

Holy Trinity Sharpness

This head was straight out of the package and it was sticky sharp, which for a 0.070 inch thick blade, it’s as sharp as it can get.

You can sharpen the Holy Trinity just by laying them flat on a file or a diamond sharpener which is really nice.

You don’t have to sharpen every blade individually and you don’t have to worry about the angle. You just lay it flat and it sharpens two at a time so you just rotate it. So, as long as you do it evenly, it’s a super easy process to sharpen

Holy Trinity Toughness Testing

So, let’s see how the Bishop Holy Trinity did against some really tough stuff.

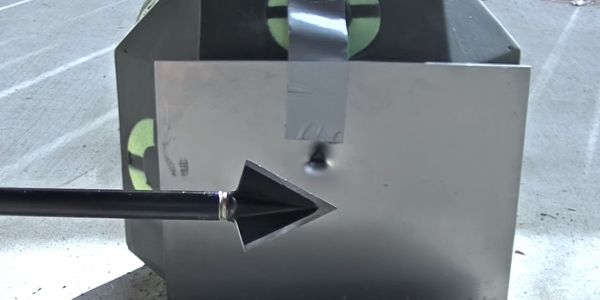

Steel Plate Test

I shot the Holy Trinity head straight into the 16-gauge steel plate. Now, 16-gauge is pretty thick, and it’s much thicker than a steel drum. I wanted to see how the tip and blades would hold up and if it penetrates through.

Porcelain Tile Test

The next test of the Bishop 200-grain Holy Trinity was shooting it at porcelain tile. So, I stacked up 5 tiles and taped them together, so that they made one chunk of porcelain tile.

I wasn’t sure what to expect, but I had heard that it’s a good way to test head toughness. Let’s see what happened.

Cinder Block Test

The next test I did with the Bishop 200-grain Holy Trinity was the cinder block test.

The Verdict Is In on the Holy Trinity 200-Grain broadhead

So, the Bishop Holy Trinity is definitely incredibly tough.

The Bishop broadheads have all been phenomenal in every test I have put them through. Quite simply, they are in a class by themselves in terms of toughness and durability.

I would say the Holy Trinity 200-grain specifically is their toughest one because of its extra beefiness and the way they’ve added those extra ridges to strengthen it. Also, because this one is 0.070 inch thick. But, with that being said, all of the Bishop Holy Trinities are extremely strong.

I typically shoot the 125-grain but this one is going to get a little more blood. With the 1 and 1/8-inch cutting diameter of those extra 3 big wedge blades, they’re going to do some serious damage, and will hold up to anything the animal world throws its way.

Further testing of Bishop’s other broadhead offerings

I did some further tests on the other models of 3-blade, 1 and 1/8 inch broadheads that Bishop Archery makes.

As we have discussed above, they originally introduced the Bishop Archery S7 Tool Steel.

Bishop Bridgeport Broadheads

And then they came out with the second line they called their Bridgeport Line. It has the same exact specs of the original Holy Trinity. It’s a 125-grain head.

They both fly exactly the same. But, the Bridgeport model is made out of 41L40 tool steel, which is actually the second most impact-resistant steel of any broadhead on the market today.

>> Click here to see all the N1 bowhunting hats!

Bishop Pipeline Series Broadheads

Bishop’s third line of broadheads is the Pipeline series. This series is made out of a really unique stainless steel that they came up with. I was looking forward to testing this head out.

It’s supposedly stronger and more impact-resistant than any other stainless steel on the market; even more than S30V and any other stainless steel broadhead out there.

There’s a significant difference in price between these heads. The Pipeline is more competitive with most other 3-blade heads on the market.

But, then the Bridgeport is a step up, and more expensive. The Bishop and the S7 are more expensive than that.

So, let’s see how all three heads performed in these tests.

The tests

In the following tests, there is a Rinehart target behind all of the mediums. That’s what’s stopping the impact.

1/2″ Plywood Test

.22-Gauge Steel Plate Test

Next, I shot them through a .22-gauge steel plate.

Timeout For Some Comparison Testing

Just for comparison sake, I decided to shoot a couple of other popular broadheads through the same mediums (wood and steel plate). I tested an Allen broadhead from Wal-Mart and the Muzzy Trocar broadhead.

Cinder Block Test

Next I tested the heads by shooting them into a cinder block. First, I shot the Holy Trinity, then the Bridgeport, then the Pipeline. I also shot the Muzzy Trocar.

The Grand Finale | The 1/8″ Steel Flat bar test

So as the finale to these tests, I shot the Bridgeport and the Pipeline into a 1/8-inch steel flat bar. ( I had tested the S7 in a previous test, so I did not include it here).

Final Thoughts

I am really impressed with what these Bishop broadheads have done. I’m also a bit surprised.

I’m especially surprised with the stainless steel Pipeline. Bishop thought they had something really good in that new steel they’ve been able to create and sure enough, it proved out.

Now, it’s really important to understand a couple of things here.

First, you might be asking, “why does any of this matter? Why are you shooting heads into steel, teak wood and concrete, stuff like that? What’s the point? It’s not an animal.

Well, that’s true. But, consider this. The Allen head that was destroyed… Is that, or another head like it what you want shooting into an animal?

Failure is not an option

Personally, I want a broadhead that I trust is not going to fail no matter what. And so, especially when I’m hunting a big animal like an elk or a moose, or a big hog or hunting in Africa on a trip I’ve invested time and money into, I don’t want a broadhead that’s going to dull or break in half, or lose a blade.

Will it work when it matters?

Secondly, you could take a head out of the box or packaging and have it shave hair like even that Allen did and like the Muzzy Trocar did and that’s awesome. But, it’s not how sharp it is as soon as it impacts the animal that matters, but how sharp it is as it goes through the animal that matters; how sharp it is when it comes out of the animal?

Some people say, “Oh, I don’t care if my broadhead gets destroyed, as long as it kills the animal.” Well, eventually, you’re going to have an animal that doesn’t die because the broadhead was destroyed. And, when your blades are getting all nicked up, they are not cutting tissue effectively all the way through.

So, you want a head that’s not just sharp upon impact, but that’s sharp all the way through that impact, through the tough hide, through the muscle and all the different forms of tissue; the tendons, the ligaments, the cartilage, and even through bone.

You want one that is going to keep penetrating extremely well all the way through, especially if it’s a big animal where depth of penetration makes a significant difference.

Bishops are worth it

So, that’s how these Bishop heads show and prove their worth. They are able to take the toughest that there is and do extremely well through it.

I still shoot a lot of different types of broadheads based on the need I have and the conditions, as well as what animals I’m going after. But what you have here is the best deal, hardened in the strongest way and you have them CNC machined in the Holy Trinity as well as their two blade heads.

And then, you have the geometric design that makes these heads extremely strong. And, they do all that also in a really short design in the Holy Trinity, which allows them to fly really well.

I hope this helps you to understand broadheads and understand these three lines of Bishops a little bit better.

Great job testing those Bishop broadheads! I recently purchased some 125 dicing drill broadheads in s7 and bridgeport steel from Shawn. He’s a very friendly and knowledgeable guy. I enjoy all your broadhead comparisons! Keep up the good work and God bless you!