By: John Lusk

My purpose in this review was to find out how the Iron Will Outfitters broadheads perform when it comes to penetration and durability.

The Original Iron Will Broadhead | Beauty In A Box

I have never held a broadhead and felt like I was about to propose. But, that’s just what I felt like when I received the Iron Will Outfitters broadheads.

The hand-made box that each broadhead comes in is the definition of quality. The broadhead lies flat in the box on a felt background. It’s really impressive.

The hand-made box gives the Iron Will broadheads a head-start in visual excellence.

But enough about the box, it was time to start checking out and testing the broadheads themselves!

Firstly, even to the eyes, the Iron Will broadhead screams quality. I have tested many broadheads and there are some that you can hold before testing and just know, “this isn’t going to be very good.” However, the broadheads from Iron Will made me go, “OK. This is top tier for sure.”

You are paying for them to be top tier, so you would expect them to be. But, these broadheads literally fit the bill.

To go straight to the testing for each Iron Will broadhead, click the appropriate link below:

- Iron Will Original

- Iron Will Wide

- Iron Will Wide Solid

- Iron Will Single Bevel Solid

- Iron Will Wide Solid Single Bevel

- Iron Will Wide Single Bevel 125 grain

Original Iron Will Head Design And Construction

The Iron Will broadhead is made of A2 Tool Steel that has been triple heat-tempered as well as cryogenically tempered to produce incredible hardness.

It has Rockwell hardness of 60 but also has an incredible resistance to impact.

You may feel like there’s a diamond inside the Iron Will Outfitters box, but it’s just a precision-crafted piece of archery beauty.

Its Charpy C-Notch score is multiple times higher than a typical stainless steel. So, it has a really good resistance to impact and it has a fairly good resistance to wear which will make a difference on edge retention. The bottom line is that it is top-notch steel.

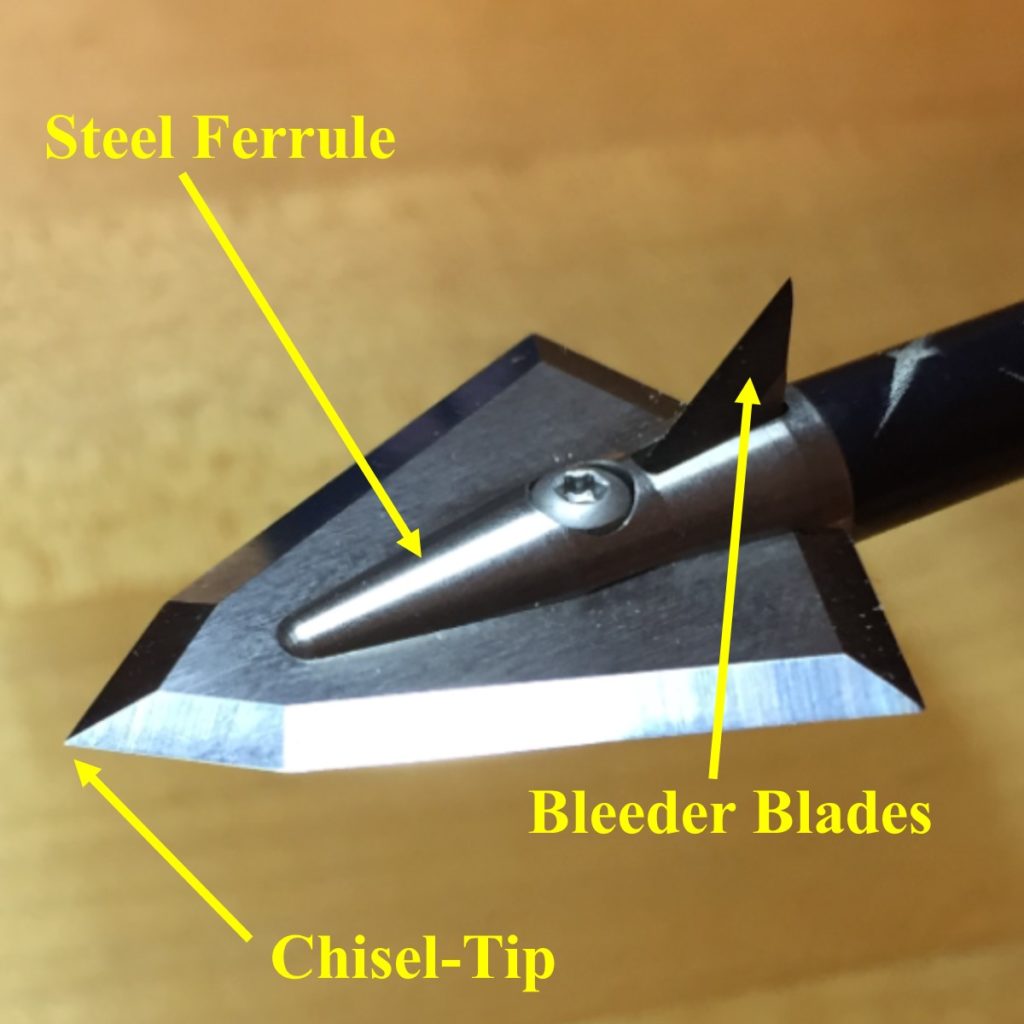

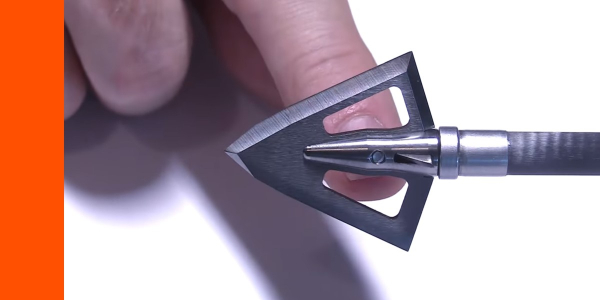

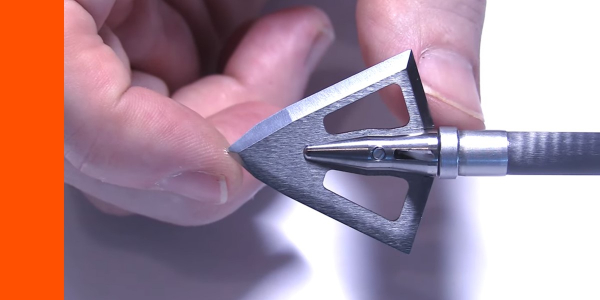

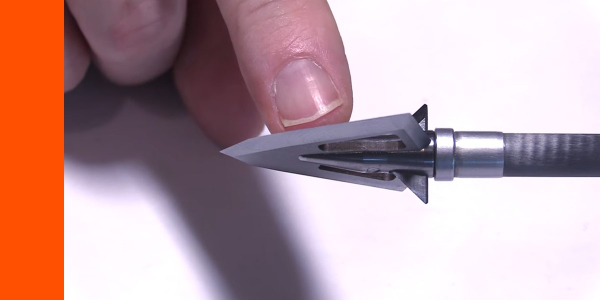

Another thing I like is that it is a “cut on contact” tip, which aids in penetration. It has two larger blades followed by two smaller bleeder blades. Both the main blades and the bleeders are really thick (0.063 inches). All the blades are replaceable as well, which is nice. It also has a solid steel ferrule.

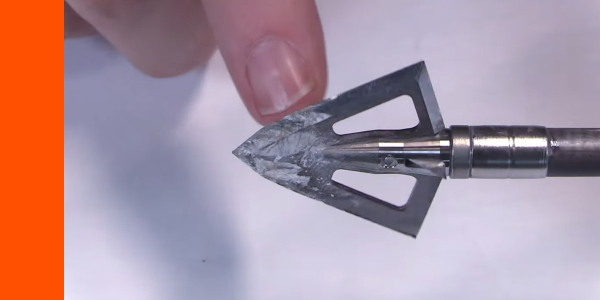

When you take a look at the tip of the broadhead itself, you’ll notice it has a chisel tip, even though it’s a 2-blade head. The chisel tip provides extra lateral strengthening as the ferrule goes up high towards the tip.

The Trade-Offs

There are a few things about the Iron Will broadhead that are not my favorite. These are observations regarding design.

First of all, with the 2-blade tip and the A2 steel, the benefit is that you are going to get great penetration. But, you’re not going to get the lateral support that you would get with a real chisel tip or a 3-blade tip where all 3 blades come together. It structurally cannot be as supportive. So, while it’s a plus for penetration, it’s a minus on durability and hard impact.

And, then the protruding ferrule… again, there’s a plus to it in that it strengthens the blade going up pretty high. But, it has a little bit of a lip to it, and I can imagine that it could get stuck, not on flesh but maybe on bone, if it splits bone or a hard material.

Additionally, it’s a component head. And again, this is a trade-off. So it’s several pieces. The set screw has no tension on it that would go against the arrow itself and into the ferrule. But, you have multiple pieces.

Now, the plus side of that is that each piece can be stamped, ground and hardened to extremely high specifications with fine-tuned machining. The negative the the multiple pieces is that, in theory, is, it’s just not going to be as strong as a one-piece broadhead, especially a CNC machined head.

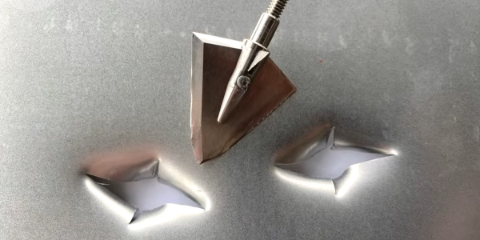

The anatomy of the Iron Will Outfitters solid broadhead.

-

N1 Outdoors® Sunrise In Tineville™ Tee

$28.99 – $32.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Tine Lines™ Elk Antler Tee

$26.99 – $29.99 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

N1 Outdoors® Trifecta Fish Arrow Tee

Original price was: $22.99.$5.00Current price is: $5.00. Select options This product has multiple variants. The options may be chosen on the product page

Iron Will (Original) Flight

In addition to the appearance and construction, I like the flight. I got to shoot these out to a hundred yards and it is extremely forgiving. I’ll put the Iron Will up there with the best heads I’ve ever shot in terms of forgiveness, if not the best.

I can pop balloons with this broadhead at 60, 80, and 100 yards fairly readily, and it groups extremely well.

But, how would the Iron Will perform in penetration, durability and hard-impact testing? I decided to test it against the best-selling 3-blade head on the market: The G5 Montec.

Penetration and Durability | Iron Will (Original) vs. G5 Montec

In my first penetration test, shot the Iron Will Outfitters broadhead into about 60 layers of cardboard with a Rinehart target behind it just in case.

The Iron Will broadhead penetrated further into the layered cardboard than the G5 Montec.

Penetration Test #1: Layered Cardboard

First, I tested the G5 Montec broadhead and then the Iron Will.

For the first penetration test, the Iron Will shined. It penetrated a couple of inches further into the cardboard than the Montec.

For that first penetration test, you really can see that the penetration of the Iron Will shined. It went through 7 layers of cardboard, which was about 1-1/4 inch further than the Montec. Afterwards, the Montec’s blades just slid right across my fingernail. They obviously had been dulled. However, the Iron Will still bit into my fingernail. That’s A2 Steel for you.

Penetration Test #2: Compressed Fiberboard

In the second penetration test, I shot both broadheads through three layers of compressed fiberboard.

The Montec has a diameter of 1-1/6 inches as does the Iron Will. But the Iron will also has 0.75 inches in the cross bleeders. The Montec has only three blades. So, the Iron Will has roughly 1.8 inches of cutting cut, versus 1.6 for the G5 Montec.

The Iron Will also penetrated further into fiberboard than the G5 Montec.

Even with the larger cut of the Iron Will, it buried about a 1/2 inch further than the G5 Montec.

So, even with a larger cuts of animal tissue, you would be getting deeper penetration into soft material as well as hard material.

After this test, the Montec was again already dulled somewhat and would not catch on my fingernail. The Iron Will, even after this second test, shaved my fingernail and was still sticky.

Additionally, the Montec ferrule bent during the test and wobbled during spin, whereas the Iron Will still spun true.

-

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Color Fade (Various)

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Diamond Plate (Various)

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Double Lunger™

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page

Durability Test #1: 16-Gauge Steel

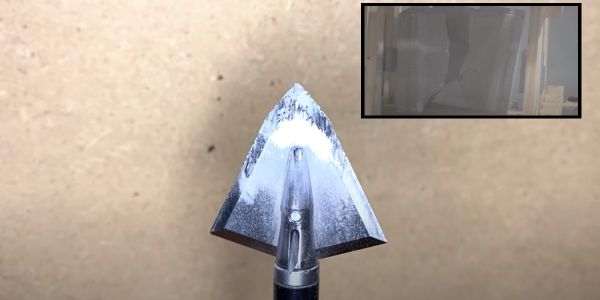

For the durability test, I shot the Iron Will into a 16 gauge steel plate.

The Iron Will had good penetration into the steel plate, but the top of the ferrule got stuck somewhat and was slightly chipped away. (Other broadheads that I have shot into the steel plate have suffered significant damage).

Here is the Iron Will broadhead penetrating a 16 gauge steel plate!

The tip of the broadhead held pretty firm. There was a little bit of a dent on it, but not as much as was expected. The Iron Will did really well compared to all the other fixed blades I’ve tested on the steel plate. The only one that has tested better is the Bishop Holy Trinity, with its 3-blade design of S7 Tool Steel.

The bleeders got a little thinned out and dinged up, but can be replaced.

Durability Test #2: Cinder Block

For this test, I shot another Iron Will broadhead into a cinder block to see how it performed on hard impact.

The Iron Will penetrated well into the cinder block. The bleeder blades did not make it into the block, so it was a relatively small area, but penetration nonetheless. The head got dinged up and the ferrule was cut, but still spun well post-testing.

The Iron Will penetrated the block, and spun well after testing.

Durability Test #3: Steel Flat Bar

For this final test, I shot the Iron Will at a 1/8-inch fixed steel flat bar. I have shot other heads into this flat bar before and the only ones to survive it have been the Bishop Holy Trinity.

The Iron Will made made a nice cut in the bar and actually penetrated the other side. The ferrule we talked about was actually embedded into the steel bar.

The head itself did not fare too well. It also did not penetrate far enough for the bleeders to touch. The blades just disappeared; I’m not sure where they went, but they are somewhere in my backyard. While the Iron Will punched a hole in the steel bar, it didn’t endure it.

The Iron Will broadhead penetrated the steel flat bar, but some components went AWOL.

Iron Will Wide

I’ve had one small critique about the original Iron Will, and that is that it’s cut size. It’s 1-1/16 inches wide. It does have bleeders as well that are 3/4 of an inch.

So what that does in a good way is it maximizes penetration and it maximizes long range flight. But, sometimes you’re not going to be shooting over 60 yards and you have no trouble getting a fixed blade broadhead to pass through an animal, but you want a bigger hole, and that’s where the Iron Will Wide comes in.

The Iron Will Wide (on left), is 1 and 3/8-inch wide. And, it has the same bleeders as the original (right), at 3/4 of-an-inch.

Iron Will Wide Flight

I was really impressed with the flight of the Iron Will Wide head. I didn’t expect it to be this good, especially at longer ranges.

Now, I will say that it’s not as forgiving, accurate, and consistent as the Original. With the Original, I can pop balloons even in a crosswind and so forth at all different ranges.

With the Wide, I’ve got to really pay attention to my form and even then, it’s a little bit touchy.

I’d feel a lot better taking shots with the Wide under 60 yards. But, as you can see, it can still work out to 80. But, on animal (mule deer, whitetail, elk, etc), I’d shoot the Original if I was going to be shooting past 60 yards.

Penetration Testing of the Wide

Here, you can see the penetration of the Wide into the ballistic gel. As expected, the Original penetrated a bit more deeply. It measures 7 and 3/4 inches. And the Wide penetrated 6 and 1/2 inches. The way I have the ruler set up there, you can’t quite see it, but that was the actual penetration, 7 and 3/4, and 6 and 1/2.

Durability of Original vs. Wide

The cool thing about the Original Iron Will vs. The Wide is, you have a choice. If you have a setup where you need to maximize penetration or you’re going after something really big and you need maximum penetration, or if you’re shooting something at really long range, man, the Original is the way to go. It flies like a dart and penetrates really deeply.

But, if you’re shooting something under 60 yards, the Wide shoots plenty well under 60 yards and it’s going to make a really big cut if you have the kinetic energy to handle it.

So, you can have something for any situation. Some people may want to consider putting both in their quiver. Say, if you are like a Western hunter, maybe you have a really long shot, well then, you can use this like a follow-up shot or something.

Here, you see the two heads after going through the MDF, of course into the gel, and then also through a 22-gauge steel plate. As you can see, man, this A2 steel is just – it’s just something. And the Wide on the right, again, has gone through a couple of deer, a raccoon skull with the raccoon in it, the raccoon skull, and a rabbit and into the ground multiple times because of those things. So these heads are just amazingly resilient and resistant to impact. They hold an edge incredibly well.

Here’s a good way to see the difference in the hole size. Quite a significant difference. Of course, the Wide on the left and the Original on the right.

The Iron Will Wide Solid Broadhead

In addition to the Wide, Iron Will now also makes a WIDE version of it’s original SOLID (unvented) broadhead. It sports a 30% greater cut than the original.

The blades, as in all of the Iron Wills, are 0.062 inch thick. The ferrules are made out of a grade 5 titanium. This is a really stout titanium that is stronger than many steels, but a lightweight material which allows it to keep the weight down to 150 grains, even in this solid model.

I tested the Wide Solid for long distance flight, edge sharpness and edge retention, for penetration, and for durability. Let’s see how the Wide Solid performed.

Here’s a good look at the Wide Solid in 150 grains. It has a cutting diameter of 1-3/8 inches x 3/4 of an inch (30% greater than the original solid). For comparison, the original solid is shown as well.

I made this edge retention test a bit challenging. After every two strokes of an Easton HEXX shaft over the edge, I did a push paper test over the blades. I gave 2 points for every time it cuts paper after every two strokes.

The Wide Solid cut paper after 10 strokes of the arrow.

In the ballistic gel penetration test, the Iron Will Wide Solid penetrated 7 inches and the double bevel Solid penetrated 7 and 3/4 inches.

In the cardboard penetration test, the tip of the Iron Will Wide Solid penetrated through the 51st layer. The Iron Will Solid with bleeders cut through 60 layers.

I shot the Iron Will Wide Solid through a .22 gauge steel plate five times. Here’s the Wide Solid after going through the steel plate 5 times. You can see it’s still in excellent shape. It basically looks brand new. And, it makes very nice holes. You can see those bleeders just widened that hole up and made a really make a nice oval cut. That’s going to create some serious blood-letting.

Here is the Wide Solid after the fifth shot through the steel plate and then after being shot into the concrete and it still spun very well. So, this head went through a lot (steel plate PLUS broke the concrete in half after the third shot). And, you can see the tip did not curl and that main blade did not bend at all. Impressive!

The Wide Solid by Iron Will is a fantastic head. I’ve always really liked the Wide 125-grain vented version but I like this one even more!

Iron Will Single-Bevel Solid Broadhead

Iron Will also has a single-bevel solid head. They have a 2-blade, as well as one with bleeder blades.

The one with the bleeder blades adds and additional ¾ of an inch of cut.

The bevel angle of these heads is 32 degrees. The thickness of the blades is 0.062 inch thick. The ferrules are made out of a grade 5 titanium.

And it’s interesting with all the Iron Wills that use that titanium ferrule, the blades are completely interchangeable. So, you can interchange the double bevels. You can interchange the Wide series. You can interchange them with any of the heads that use that titanium ferrule.

-

N1 Outdoors® Duck Camo Block Logo Heavyweight Hoodie

$54.00 – $58.00 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® “Sunset Mountain” Pullover Hoodie

$49.00 – $52.00 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Est. 2014 Forest Camo Heavyweight Sweatshirt Hoodie

$54.00 – $58.00 Select options This product has multiple variants. The options may be chosen on the product page

The blades themselves are made out of an A2 tool steel. They are brought to a Rockwell hardness of 60, which is extremely hard which allows them to get really, really sharp, a fine edge on them.

Because the blades are made of the A2 tool steel, they have an incredible resistance to impact. That’s especially important with a single bevel, because as the head rotates, there’s a lot of pressure that is put on the blade’s leading edge in the rotation.

This is the 125-grain version of the Iron Will single-bevel solid broadhead. They’ve got a 2-blade and then also one with bleeders (both shown above). They both have a cutting diameter of 1 and 1/6 inches. It has the bleeders. The bleeders on the 4-blade add an extra 3/4 of an inch cut. The beveled edges on these heads aids in rotation during flight.

In stainless steel or carbon steel broadheads, you’ll often see an edge chatter, or bumps or dents that are in that leading edge as they hit a hard substance. But, given the resistance to impact of this steel, that really should not be an issue.

So, I was eager to put these to the test. I tested them for long distance flight, for edge sharpness and edge retention, for penetration, and for durability. Let’s see how these single bevel Solids performed.

Here are the two single-bevel heads at 70 yards, aiming for that lower left circle. As you can see, they grouped really well. Really great flying heads.

The Iron Will Single Bevel cut paper after 10 strokes of the arrow.

The Single Bevel without bleeders penetrated 8-1/4 inches. The one with bleeders penetrated 7 and 1/8 inches.

The Iron Will Single Bevel with bleeders cut through the 54th layer of cardboard. The Iron Will Single Bevel with no bleeders penetrated through the 56th layer. Both of the Iron Will single-bevel heads rotated just about 40 degrees, almost identical rotation.

Here, you can see a really good look at the wound channel that’s created by these single bevels. Here, the 2-blade is just your classic S-cut, nice hole. And then here with the bleeders, a nice S-cut going both directions. I’m really glad they made the bleeders single bevel as well, because that is a wicked-looking wound channel. Wow! And as for the heads themselves, you see here in the 2-blade, you literally can’t even tell it has been shot, let alone through steel plate. The onee with the bleeders got a bit more of a rotation and got a little bit more dinged up on the edges. But it’s almost entirely cosmetic.

The Single-Bevel just embedded in the concrete during the cinder block test.

Here’s the head after going through the concrete. The tip did not curl at all and it held up really well and still spun true. (Since the concrete would keep the bleeders from impact, I did not shoot the 4-blade head into the concrete, since it’s essentially the same head).

-

N1 Outdoors® Bucket Bite™ Leather Patch Hat

$29.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Put A Hook N1™ Fish Hook Leather Patch Hat (Kelly Green/White)

$29.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Elk Antler Leather Patch Hat (Duck Cloth/Camo)

$32.99 Select options This product has multiple variants. The options may be chosen on the product page

Single Bevel Solid vs. Double Bevel Solid Battle

I decided to test the 100 grain Iron Will Solids head-to-head!

These heads are identical in every attribute except the beveling.

I used my Bowtech CP28 for most of the shots and the Bowtech SR6 for some others. I used the Bishop Archery FOC King Arrows for most of the shots as well and the Bishop Archery FAD Eliminator for the really hard impact stuff.

The ferrules in these are made out of titanium, which has a really good weight to strength ration. That’s to keep them at a 100 grains.

The blade thickness is 0.062″ both in the bleeders and in the main blades. The cutting diameter is 1-1/16″ this way and 0.75 or 3 quarters of an inch from bleeder tip-to-bleeder tip. this way.

There is one set screw that is not load-bearing. It just holds everything in place there but you don’t have to worry about that pin breaking or anything because all of the pressure goes back on to the arrows insert.

Now, what’s interesting about the 100-grain is they’re the same width, same size cut and the same blade thickness as the 125-grain and yet, they have a shorter overall profile. And, that’s going to make them a bit more forgiving in flight because there is less surface area. I would imagine it’s going to help them to penetrate a bit more because there’s less friction on the blade surface.

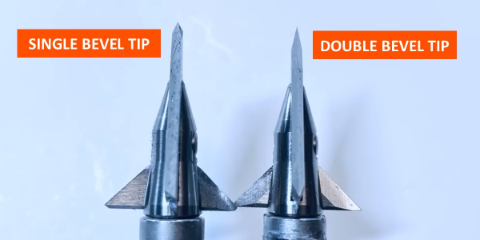

Now, one thing I will note is if you look at the double bevel, you can notice that because of the double beveling, the very tip gets really narrow. It’s really pointy, which is impressive.

The single bevel. OK. Same material, same dimensions, but rather than having a double bevel on every side, it has a single bevel and that is brought a bevel angle of 32 degrees which is a really good balance of penetration, sharpness, and still getting a bit of a rotation.

Now as mentioned earlier, you can see that the end of it stays thicker longer because it has a bit stouter Tanto tip to it being single bevel in this design. I would imagine that’s going to make that tip just a little bit more durable, though I expect both of them typically really durable.

So, I was eager to pit these against one another!

Flight Forgiveness Test (1 Field Pt then 2 DB, then SB @ 40 yds):

Here you can see the flight test results from 40 yards. The unmarked arrow on the farthest right is the field point.

Initial Sharpness

Pre-test sharpness of the Single Bevel.

Pre-test sharpness of the Double Bevel.

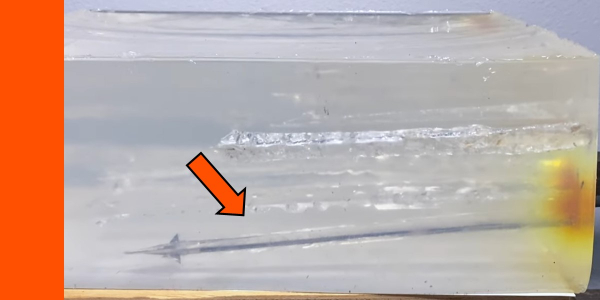

Penetration Test 1 (2/3″ rubber mat, 1/2″ MDF, FBI Gel):

They each penetrated exactly 7-1/2″ (although it might not look like it from this angle.)

Edge Retention Test (sharpness after Penetration Test 1):

Single Bevel post-test sharpness was 200.

Double Bevel post-test sharpness was 225.

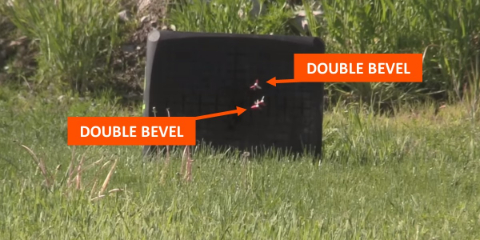

Penetration Test 2 (layered cardboard):

They each penetrated through 68 layers of cardboard.

SB Rotation Test ( FBI Gel):

The single bevel rotated 15 degrees at 10-1/2″ of penetration.

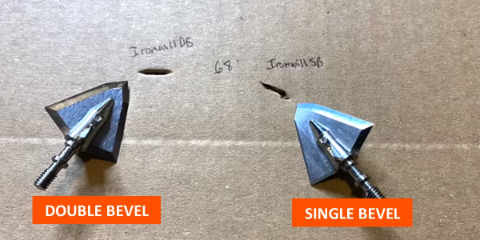

Durability Test (1/2” MDF, 3 shots):

Both of the heads are in absolutely perfect shape after going through the MDF 3 times.

Durability (22 ga steel plate, 2 shots):

Here are both of the heads after going through the steel plate 2 times and they both did very well. The Double Bevel is on on the left and lost the very tip of the blade. The single bevel on the right got a little bit of edge chatter on one of the top edges. But, otherwise, they both did excellently.

And here are the holes from the Double Bevel on the steel plate as well as the Single Bevel. You could it got a bit more of an S-cut due to that single bevel rotation.

Durability Test (Concrete 1 Shot):

Here are both heads after going through the MDF 3 times, the steel plate twice, and the concrete block. Notice that the tip is broken off of the Double Bevel. That’s not from the impact, but rather from me trying to get it out with a hammer and a chisel. It still spun true. The Single Bevel didn’t stick in the concrete, but that’s not a knock on the broadhead. There are so many variables that affect that. It took a huge chunk out of the concrete and it stayed perfectly intact and spun true. I was really impressed with the durability here.

Iron Will Wide Solid Single Bevel Broadhead

Originally, Iron Will came out with a Double Bevel and then they came out with the Double Bevel Wide. Then they came out with the Single Bevel and everybody was like, “Are you going to do a Single Bevel Wide?”

They said, “Ah, maybe one day.”

Well, now is the day.

So, once it came out, I was super eager to put this head to the test and see how it performed.

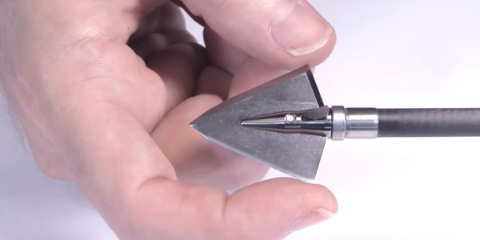

The Iron Will Wide Solid is a really cool-looking broadhead. It’s made of A2 tool steel. With A2, you’re getting a great impact resistance. And, then in terms of blade thickness, you have 0.062 inch thick blades and bleeders, which is really nice for a wound channel, as well as durability.

It’s single-bevel-sharpened all around on the back as well as the bleeders at a 32-degree bevel. So, a good balance of maintaining the sharpness, as well as generating some torque in that rotation as it penetrates. It has a Tanto tip to give it extra durability.

The dimensions of the Wide, just like the Double Bevel Model, are 1-3/8 inches in the main blade and then 3/4 of an inch in the bleeder. So, the total cut is 2-1/8 inches, which is a really nice size cut. I’ve always liked the Wides for that.

In addition to the wide cut, you’re going to get some rotation, which with this extra diameter here and that flare, and the thickness in the bevel angle, I thought it would probably get some pretty decent rotation.

This head is 150 grains, because they wanted to keep the blade solid. They could have saved some weight if they had made them a cut-out and vented, but I’m glad, at least in this model, that they kept it solid.

So, the head being all solid is going to make it quieter in flight and it’s going to make it a bit more durable.

Let’s see how it performed.

Flight Forgiveness (I field pt then I broadhead @30 yds):

As you can see, the Wide Solid Single Bevel head flew right with the field point.

Initial Sharpness

It took only 175 grams of force to cut through the wire which is a 10 on a 10-point scale!

Penetration Test 1 (2/3″ rubber mat, 1/2″ MDF, FBI Gel)

The Wide Solid Single Bevel head penetrated right at 8 inches. I know it may not look like that the way, with how it’s lined up with the camera, but 8 inches is the actual measurement.

Edge Retention Test (sharpness after Penetration Test)

It didn’t take any additional force to cut through the wire, so that gets a 10 on a 10-point scale!

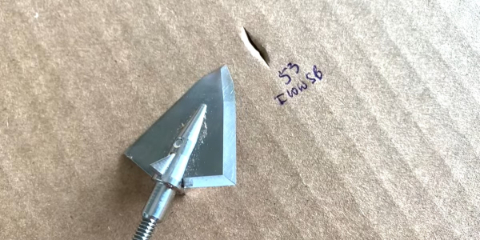

Penetration Test 2 (layered cardboard)

The Wide Solid Single Bevel penetrated through 53 layers of cardboard.

Angled Shot Test (1/4″ MDF/Carpet)

No problem at all with the angled MDF/carpet penetration test.

Rotation Test (Clear Ballistic FBI Gel)

It rotated 38 degrees and penetrated 10-1/4 inches.

Durability Test (1/2″ MDF max 3 shots)

It’s in perfect shape after 3 shots to the MDF.

Durability Test (22 gauge steel plate max 2 shots):

So, here it is after the 2 shots through the steel plate. And structurally, it held together very well. And look at those holes in the steel plate. It made really nice, classic S-cut holes, both with the main blades, as well as the bleeders. That will open up a really nice wound channel that’s going to be hard to close up. It did experience a bit of edge chatter and that’s because of that 32-degree, which is really good for cutting. It’s super sharp, but it does create or allow a little bit of edge chatter on a super hard impact. It’s not much, but each of the 4 blades experienced some edge chatter.

Concrete Test

So, here is the Wide Solid Single Bevel after all the durability tests. It went through the MDF 3 times, through the steel plate twice, and then cut a chunk of the concrete off the block. And man, it held up really well. I was a little concerned that with it hitting at an angle like it did, that it would have bent, But, man, it held up extremely well! The only signs of damage are from the steel plate, where there was a bit of edge chatter on both of the main blades, as well as on the bleeders. But man, with the concrete test, it just did extremely well. I was really impressed with the durability.

Iron Will Wide Single Bevel 125 Grain Broadhead

For this test, I used my Elite Era compound bow and a Killer Instinct SWAT X1 Crossbow for the flight testing. I used Bishop Archery Arrows and bolts for all the different testing.

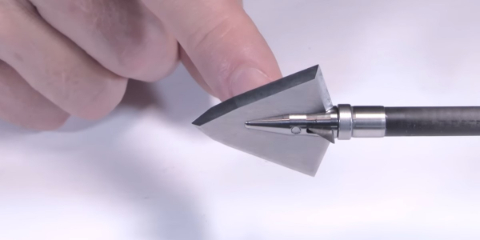

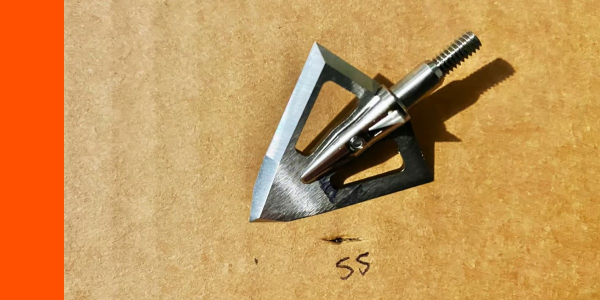

Iron Will Wide Single Bevel 125 grain Up Close

This is a really nice broadhead. I say it all the time, but when you open up the package of an Iron Will after spending quite a bit of money, you do not wonder where that money went. You just go, “Oh, yeah. This was money well-spent.”

Let’s zoom on in here and check out this new Iron Will Wide Single Bevel and then put it to the test.

First of all, the materials… the blades are made out of A-2 tool steel and they’re brought to a Rockwell hardness of 60. Now, A-2 tool steel is really superior to the typical like 420 stainless steel that’s used in most broadheads just because it can withstand a lot more impact. So it’s a really great steel to use in a broadhead application for its ability to get super sharp, be super hard holding edge, as well as resist impact like that.

The ferrule is a hardened steel ferrule and the blades are 0.062″ thick, so pretty thick blades. In this 125-grain model, you notice that you have a bit of venting. That’s probably going to give a bit of a whistle in flight. However, I don’t really worry about arrow flight noise. I’ve never seen it to be an issue in the field so it’s not a problem for me. It’s probably going to make a more forgiving in flight as well. But I looked forward to testing the flight.

The cutting diameter of the Wide Single Bevel 125 grain is 1-3/8″. That’s really a nice, good, wide cut for a fixed blade broadhead.

As for the bleeder blades, it’s a 3/4″ cut in that direction. That may sound small, but it really opens up a nice wound channel. The total cut is 2-1/8″, which is really nice again for a fixed blade broadhead.

The overall length beyond the edge of the arrow shaft here is 1.39″ so not super long, not super short, right in between.

The single bevel is 32 degrees. So for resharpening, the Stay Sharp Guide makes a 32-degree sharpener largely for this, but there are others that have the 32-degree bevel as well. And man, it works very well with this broadhead. The little bleeders are single bevel as well just to help with the rotation and the sharpness.

Flight Test (1 field point & 1 Broadhead 30 yards, Killer Instinct SWAT X1 Crossbow 675 gr Bishop Bolt, 300 fps):

In the flight test, it’s so close to the 9-ring, so I gave that an 8.5.

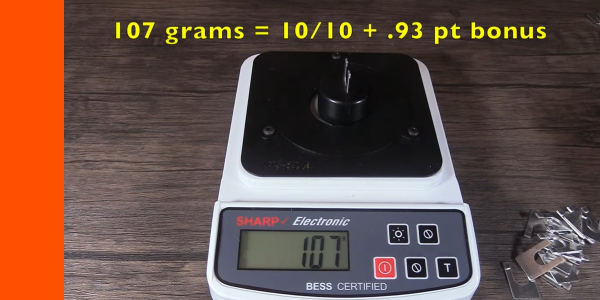

Edge Test I, Initial Sharpness Test (Grams of force to cut copolymer wire):

It only took 107 grams of force to cut through the wire which is a 10 on a 10-point scale. Plus, it gets a 0.93 point bonus. That may be the sharpest. Certainly, one of the sharpest I’ve ever tested.

Penetration Test 1 (2/3″ rubber foam mat, 1/2″ MDF, FBI Gel):

The Wide Single Bevel 125 grain penetrated 8″ into the ballistic gel.

Edge Test 2, Edge Retention (sharpness after Penetration Test 1):

It took an additional 34 grams of force to cut through the wire, which is a 9.32 on a 10-point scale.

Penetration Test 2 (layered cardboard):

It penetrated through 55 layers.

Durability Test 1 (3 shots 1/2″ MDF):

The head is in perfect condition after the three shots through the MDF.

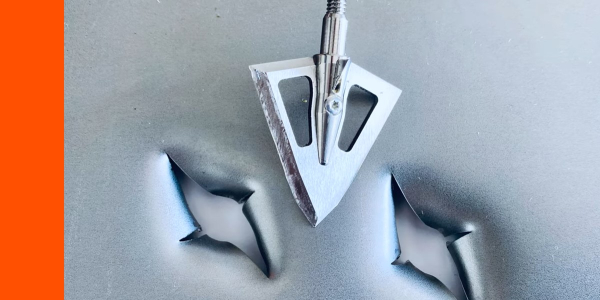

Durability Test 2 (2 shots 22 gauge steel plate):

And here it is after the 2 shots to the steel plate and the head is in almost perfect condition after those 2 shots. There’s a slight bit of edge chatter on one of the main blades and then on the bleeder as well but very little. And then you can see really cool holes, just a classic S-cut of that single bevel. Plus, the single bevel bleeders, that’s going to make a nice wound channel that’s hard to close off.

Rotation Test (Clear Ballistic FBI Gel):

Interestingly, there was no rotation in the gel. I’m not sure why that is. Maybe the venting in the blades and the wide cut, maybe that just prevented it in the gel. I did notice quite a bit of rotation in the target when I shot it into that. But the rotation here was zero.

Durability Test 3 (1 shot cinder block):

Here it is after all the durability testing. Still spins perfectly through. Man, it held up very well even with that cut on contact tip. It went pretty deeply into the concrete, with slightest bit of edge chatter, but man, it did very well.

Final Thoughts On The Iron Will Single Bevel Wide 125 Grain

So what do you think? Man, it performed really well, as expected. That might be the sharpest blade I’ve ever tested. I couldn’t believe how sharp that was. And it held its edge fairly well too and had incredible durability, even with the venting. It lacked a little bit in flight and in penetration. But, that’s what you expect with a big wide broadhead. But, if you have the juice behind your setup to drive it deeply into big animals, this really is a good choice.

Conclusion

The Iron Will was very forgiving, flying very well at long range out to a hundred yards.

In the penetration testing, it out-penetrated the G5 Montec, which has a smaller cut than the Iron Will does. The head also did really well against the 16-gauge steel plate. It did better than all the other fixed plates I’ve tested with the exception of the Bishop Holy Trinity.

And then in terms of a concrete or the cinder block, it did really well, sticking deeply into the block with the two main blades, remaining strong.

The Wide Solid and the Single-Bevels also performed amazingly well.

The only place that the original failed (and you can’t really call it a failure) was when it was shot into the 8-inch steel flat bar, where it just kind of fell apart.

But overall, I have to give these heads an A+. I put these broadheads up there towards the very top!

Hey John. I wanted to say thanks for all that you do. It takes a lot of time, which is so precious. I have always shot montecs and stinger buzzcuts without to many complaints. I have always had the philosophy of one and done with broadheads. I am looking to upgrade this year after watching several of your reviews. I am torn between the qad exodus and the iron will. When it comes to iron will, it gets a bit confusing. Originally, I was sold on the solid head. Then came the wide and now single bevel. I will be hunting whitetail primarily and from a treestand. My bow, elite synergy, is not aggressive by any means. My specs are 28/70 with a 450 grain axis 340 which has a 100 grain head. I can’t increase front weight anymore on this system so I am torn on going with a 100 grain exodeus or s100 or moving up to a 300 spine so I could shoot a heavier head and go with the single bevel or wide solid at 150 grains. Iron will sure looks to produce a top end product, they just make it hard to decide with so many options. Thanks and God bless!

Great info on a head I’ve been hearing a lot about. In your opinion do the bleeders increase or decrease lethality on the single bevel heads. I thought penetration would be higher as it would reduce arrow shaft drag but it was actually less. So more penetration or more inches of blade cutting?

Do you happen to remember the collar and insert setup for the arrows in the first picture? And the diameter of the arrows. I’d like to build some skinny’s but don’t know where to begin

Trey, Iron Will recommends their impact collars with HIT inserts, either 4mm or 5mm.

Keep up the good work I watch some of your other tests. I own the Iron will V100. They fly like a dart I use one for practice. Can’t wait to try them on game.

Thank you for visiting our blog, Gregory. The Iron Will is a great broadhead for sure.

I just wanted to say thanks for making a broadhead that has outstanding penitration. I hunted cape buffalo last September in South Africa. the shot was 19 yds slightly quartering to me .I got 22inches of penitration and the bull went down in 50yds .so thanks again.

Congrats on your cape buffalo, Sean!

FYI – That’s not a chisel point. It’s a ‘Tanto Tip’. It is designed to help penetration & prevent curling of the tip. It is See: Factor #11 of Dr. Ashby’s “12 Factors of Penetration”. Single Bevel broadheads are designed to split bone & get passthroughs.Cardboard, concrete & steel not so much. But, the review is thorough.

Only thing not covered in depth here is the noise difference with these heads. I shoot the solids because the vented are extremely loud. Great broadheads and great detailed review. Thank you