It happens every deer season. Someone walks down the hunting aisle of a local sporting goods store, sees the deer scents and attractants section and begins to wonder how they can tip the odds in their favor during their next hunt.

When it comes to using scents and attractants, success comes from knowing the right scent to use at the right time. For example, you might not want to use an estrous scent in October, but it might be the best thing to use in Mid-November.

Let me give you an example…

It’s not just the scent that’s important… it’s using the right scent at the right time!

A Lesson In Scent Usage

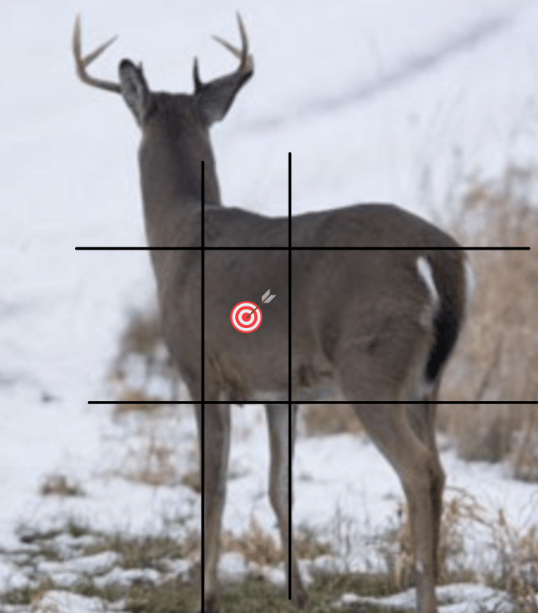

It was the third week of October in Indiana, the pre-rut was on, and the deer were fired up. I had just climbed into my ladder stand, hung up my backpack, and pulled up my bow. As I prepared for this afternoon hunt, I had no idea what was about to happen.

I had just pulled an SD card from one of my trail cameras on my way to the stand. I had gotten to the stand a little earlier than normal, so I figured I’d have time to go through some of the pictures and check activity from the previous couple of days.

Mock Scrape Magic

I had hung a dispenser of a new scrape blend scent that we were trying out and the results were extremely positive. I had bucks coming to this mock scrape nightly, but a new buck had shown himself that I had not seen before.

As I was going through the pictures, I randomly picked my head up and scanned the woods I was hunting, as well as a nearby cornfield.

Mock scrapes an provide some of the best buck intel you can get.

Then, I saw movement.

I got ready and then a deer came into full view. It was a spike, and he was on the move. So, with the opportunity of some interaction, I let out a few soft grunts. He stopped and looked, but that was all.

I decided to see what he would do if he heard a bleat, so I did. He turned and came in on a string.

Now, on my way to the stand, I had broadcasted some Battle Ballz in front of me. When the spike hit the scent; he walked in figure 8’s trying to pinpoint the source.

Success using scents and attractants comes from not just know what scents to use, but specifically when to use them.

Bleat, Grunt, Broadside

That’s when the hunt changed even more. While watching this young buck walk around in circles, I looked to my left and saw a second deer. It was him, the 9-point buck I had seen on my SD card just saw on my SD card just moments earlier!

I grunted at the buck and he put on the brakes. He didn’t look like he was going to commit, until I bleated once again. This bigger buck wasn’t about to let a little spike be near a willing doe, so he turned and walked in.

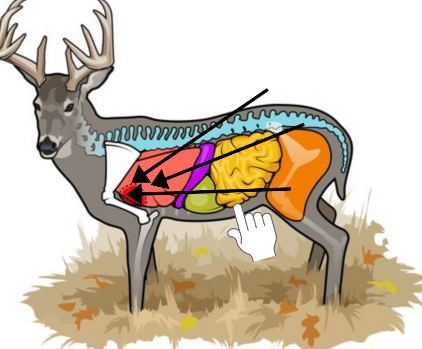

The buck gave me a clear, 35-yard broadside shot. Let’s just say I recovered him 125 yards away.

Thanks to the scent I had spread on the ground earlier, those bucks were able to keep their minds and their focus on other things. The grunt call, coupled with the scent, allowed me to take this nice 9-pointer.

As you can see, each “tool” we haul into the woods can make or break our success and overall hunting experience. In this case, the scent was the difference maker. But it’s not just the fact that there was a scent involved. It’s that it was the right scent at the right time.

>> Get the N1 Outdoors Licking Branch Buck tee

You see, this was mid-October, and my scent selections were a scrape blend, and Pay Dirt, a fresh earth scent, (I also used a dabble of another scent we were also testing for the next season.) As scrapes were popping up daily, one of our buck tarsal scents could have been another good choice.

On this hunt, the cover scents proved extremely effective, as a slight breeze was blowing straight toward those two bucks that afternoon.

Please note that it’s very important to follow your state’s laws when using scents and attractants. For example, Indiana’s game laws dictate that you can’t pour scent on the ground, but you can use in a scent dispenser which, makes the scent non-edible.

-

N1 Outdoors® “Outdoor Npressions™” Boot Print Tee

Price range: $24.99 through $28.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Block Logo Tee

Price range: $22.99 through $24.99 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

N1 Outdoors® Western Hunter TriBlock™ Tee

Original price was: $22.99.$5.00Current price is: $5.00. Select options This product has multiple variants. The options may be chosen on the product page

What Scents To Use… And When

When hunting with scents, I recommend the following guidelines, to ensure the best hunt possible.

Beginning Of The Deer Season

When deer season starts, regardless the month, use food scents!

Food scents are what separate a scent company from a urine company. What do I mean? Well we all know that urines have a time and place, but urines (deer, fox, skunk etc.) are used mostly during hunting season. A food attractant, however, can be used any time of the year.

Now, why would you want to attract deer any time of the year? The answer is simple, scouting.

Food Scents + Minerals

Scouting cameras are used more than ever before, and having a way to attract deer to those cameras are just as important as the camera itself. Lots of people say they use mineral or salt licks. Yes, using those is a great idea. Food scents however, can last for such a long time – even longer than mineral – because when used in a scent dispenser, the scent is protected from weather, such as rain or snow.

>> Get the Hide ‘N Seek Buck tee

Now, using scent with mineral is a deadly combo. We’ve found that using scent at your mineral site attracts game to that location faster, and from a further distance. This is helpful when taking deer inventory, promoting antler growth, and scouting for sheds. As I like to say, “the scent brings them in, but the mineral keeps them there.”

Pre-Rut

In mid-to-late October, as bucks are starting to rub and scrape, and pre-rut action is in full-swing, use scrape and tarsal scents.

During this time of year (pre-rut), scrapes are one of the best locations to use scent that you could ever ask for. The reason? Well, because scrapes are spots that you can predict bucks will visit.

I’ve kept a scrape active for months by changing my scents up through the various stages of the rut, drawing in countless big bucks. Use multiple scents together to simulate buck and doe activity. For example, when using a scrape blend or buck with tarsal, try adding some fresh dirt as well. By doing so, you will give the impression that the buck was just there, and you might just be able to get that dominant buck to shrink his home range and visit that scrape more often.

-

Product on sale

N1 Outdoors® Whitetail Sugar Skull Tee (Black/Columbia Blue)$19.00

N1 Outdoors® Whitetail Sugar Skull Tee (Black/Columbia Blue)$19.00 -

N1 Outdoors® Tine Lines™ Elk Antler TeePrice range: $26.99 through $29.99

N1 Outdoors® Tine Lines™ Elk Antler TeePrice range: $26.99 through $29.99 -

N1 Outdoors® Fish Arrow Patch Rope Hat$29.99

N1 Outdoors® Fish Arrow Patch Rope Hat$29.99

During The Rut

The beginning of November is a great time to use this estrus doe scent. However, because all does don’t come into estrus time, Buck Nuggets and Battle Ballz are also a great choice through first of December, or what is sometimes referred to as the secondary rut.

Post-Rut

Post rut, in my opinion, is one of the hardest time of the year to hunt. Temps are dropping, deer are tired, and food is scarce. During this time of year, I switch gears and go back to the food scents, using them like I did in the early season. Remember, tree foliage is bare during this time of year, and anything you can do to draw the eyes and nose of a whitetail is critical.

Hide Yourself… With Food

One tactic is to hang a dispenser of food scent where I would want to attract the animals, and hang the same scent in the stand or ground blind with me. Now I’ve doubled the attractant and doubled the cover scent at the same time.

Food scents are a good cover scent as well. So what if you walked into the woods smelling like apples, sweet corn, or acorns? That doesn’t sound too bad at all!

A comment I hear a lot is… “How will apple scent work if you don’t have apple trees on your property? No way Jose!”

Well, let me ask you a question. Do you know what a steak smells like? If all of a sudden you smell a steak, what’s the first thing you think? Probably something like, “Man that smells good… where’s that coming from.” You don’t think “nope, that couldn’t be a steak… there’s no butchered cows around her.”

Well, deer have the same thinking.

Scent Control Is Key

Proper scent control starts at home! Clothes stored in a sealed container with a food or cover will lessen the human odor you leave while walking, sitting, working or scouting in the woods.

Tips To Remember

- Use food scents as an attractant as well as a cover scent.

- Use cover scents all year long

- While using scent in or around a scrapes, use multiple scents. Try using a buck and doe combo in your scrapes. Another trick is use a buck scent and dirt scent at the same time.

- Don’t be afraid to experiment with different scents, even in the off-season. Scent sites are very effective ways to scout shed heads after the season ends.

In Conclusion

Hunting scents surely have a time and place. Keep in mind that your camo, tree stand, bow, and hunting scents are all tools we as hunters can use to have more success in the field and possibly create opportunities you’ve never had before.