There is no such thing as bad weather, only inappropriate clothing for the conditions.

While you might think you only need a warm jacket when venturing into the great outdoors to go hunting or fishing during the cooler months, there can be much more involved in keeping yourself warm and comfortable.

Hunting, fishing or camping in the cold weather requires a knowledge of how to best layer clothing so that you can stay warm.

When the time comes to plan your next hunting trip into the wilderness, take a moment to consider the following information, so that you can learn all about how to layer winter clothing to feel comfortable enough to explore all that nature has to offer.

How to Remain Warm in the Great Outdoors

When you put on warm clothing to head outside, your goal should always be to manage moisture, maintain your heat level for comfort, and create a barrier between the elements and your skin.

You might enjoy being alone in the outdoors… you just don’t want to be COLD and alone!

Not all cold-winter clothing is created equal. So, purchasing high-quality outdoor garments from well-known companies like Kryptek and others is a critical component of remaining warm in the great outdoors, but it’s also helpful to understand the science behind retaining your body heat to know how to wear your clothing appropriately.

You may not have the anatomy of a deer to keep you warm in cold conditions, but you can learn to layer clothing in a manner that protects you from the elements.

During winter, you’re often faced with many challenging elements, such as wind, rain, and cold temperatures. Heat is easily transferred from your body into the environment, and it’s easier to lose heat than it is to retain it.

So, whether you’re ice fishing or hunting, you need to have knowledge of how sweat affects your body and heat levels. Body heat can be pulled away from your body much faster when it’s wet with perspiration than if it were dry.

Prevent Moisture to Stay Warm

One of the best ways to stay warm, regardless of how you layer your clothing, is by being cold before you begin your hunting trip in earnest. If you add all your winter layers and then stand in front of a heater before venturing outside, you might start sweating and lose much-needed body heat.

Moisture is the enemy when it comes to staying warm in colder weather, as it robs you of body heat.

So, as challenging as it might be to immediately venture outside to start hiking once you’ve put on your multiple layers, it can be essential for giving your body the best chance of retaining its heat.

Layer Your Winter Hunting Clothing Strategically

When you’re trying to dress warmly in cold weather, it can sometimes feel like you have to pack an entire closet full of clothing when you go on a winter hunting adventure or that you have to wear multiple layers until you’re no longer comfortable.

However, if you apply the right layering strategy, you might be surprised at how easy it can be to prepare for an outdoor trip.

Before heading out, read up on the weather conditions you can expect. This allows you to take all necessary precautions with supplies and provides insight into the type of clothing you need to take with you and what to wear when you set off.

You’ll need to continually layer up and down on most hunting trips. Take note of how your body is feeling, and when you’re feeling too warm, take off a layer before you start sweating.

If weather conditions change and rain or snow sets in, you can add more layers from your hunting backpack, including a waterproof jacket to keep your mid layers warm and retain your body heat. Weather conditions can change rapidly, so you may be layering up and down throughout your hunting trip.

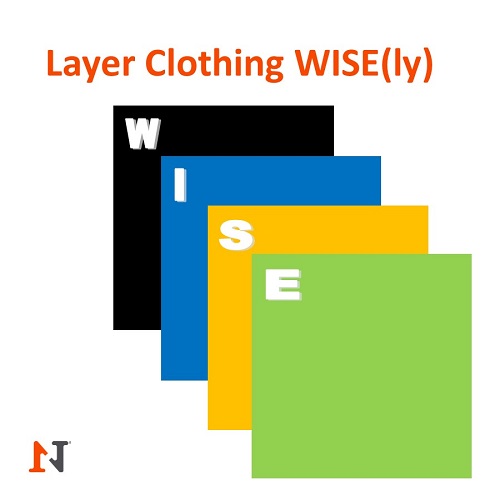

Adopt the W.I.S.E System

If you’re new to hunting, it may not be immediately apparent which clothing you should buy to remain warm, dry, and comfortable.

However, you might have a much easier shopping experience when you familiarize yourself with the W.I.S.E system. This system involves:

- Wicking – Next-to-skin base layers

- Insulating – Mid layers, such as fleece or a down jacket

- Sheltering – Rain jacket and rain pants

- Extra – Additional layers in case of an emergency, such as an unexpected snowstorm

The W.I.S.E system will give you a fundamental understanding of the basic garments to purchase, but don’t forget to buy wool socks, waterproof boots, hats, and gloves.

Choose Your Base Layer

Now that you’re aware of the garments you require for the W.I.S.E system, you can learn more about each layer and how it contributes to your overall warmth, dryness, and comfort.

A base layer is a snug-fitting set of garments designed to wick sweat away from your skin to keep you dry.

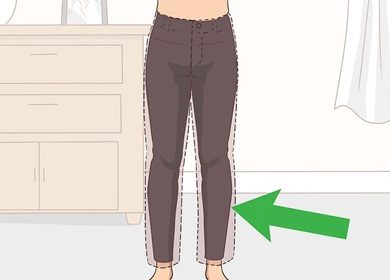

When choosing a base layer, go with wool, silk or synthetics, rather than cotton (photo credit: Wikihow.com)

While cotton can be a preference for everyday wear, it’s less suitable for outdoor activities like hunting.

Instead, opt for base layers featuring wool, silk, or synthetic fabrics. Your top base layer can be a long or short-sleeve shirt and leggings with these materials, paired with a high-quality pair of synthetic or wool socks.

Choose Your Insulating Layer

Equally as important as your base layer is your insulating layer. This layer prevents the outdoor environment from taking your much-needed body heat.

The insulating layer will help maintain valuable body heat while in the cold weather. (photo credit Wikihow.com)

Typically, you would wear a wool or microfleece top, a puffer jacket, and fleece leggings. You can also pair your insulating layer with a wool or fleece hat and neck gaiter, glove liners, and insulating socks.

Choose Your Sheltering Layer

If you are going on a hunting or fishing trip, you certainly like to see favorable weather conditions. However, weather conditions can certainly change, and sometimes rapidly.

Wearing a sheltering layer is critical in protecting the insulating layer underneath. (photo credit: Wikihow.com)

You might be caught out in the rain or snow when you least expect it, and you need to protect your insulating layer at all costs.

Pack a sheltering layer, and you can be prepared for any eventuality. Typically, this layer consists of a pair of rain pants and a rain jacket, both of which need to be waterproof to remain effective.

Best Materials for Winter Outdoor Clothing

When there are so many different types of outdoor and hunting clothing for sale, it can be hard to know what will be the most comfortable and practical. While there are many desirable options, some stand out more than others.

For example, merino wool, a natural fiber sourced from sheep, is a moisture-wicking base layer that is odor-resistant and temperature regulating.

When adventuring outdoors in colder weather, merino wool is a great moisture wicking base layer that is also odor resistant.

You might also consider synthetic fleece as a mid layer option, which is both affordable and warm. Although, it’s not an ideal wind-resistant layer.

Synthetic and down jackets can be an effective insulating mid layer, while nylon is ideal for keeping you dry. Some manufacturers create special membranes for nylon to form waterproof jackets for winter use.

Final Thoughts On Layer Clothing For Cold Weather

Layering winter clothing is an integral part of preparing for any outdoor adventure or hunting trip.

so, before you begin planning your next trip, take the time to make sure you’ve got a full closet of winter options to keep you warm, dry, and protected from the elements.

Remember the W.I.S.E. system and have fun outdoors!