In this review, I took an in-depth look at the Muzzy Trocar broadheads.

I know, the Muzzy Trocar head is not new. It has been around for a long time, and I’ve used it in some of my other tests, but I’ve never done a comprehensive test on it alone. So, that’s what I did.

Muzzy Trocar design specs

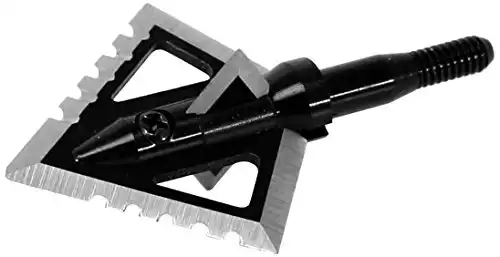

The Muzzy Trocar and it’s a pretty cool-looking head. And as you can see, it has a short overall profile, which is going to aid in flight.

It also has offset blades. In the above picture, you can see that the blades are arranged in a right helical offset pattern, which helps with rotation and aids in flight, keeping them more accurate, due to a spinning effect. This feature makes it different than many other 3-blade broadheads.

And, then within the animal or any medium it hits, the blades will continue to rotate. It’s going to create a decent wound channel inside the deer or other animal as well.

The ferrule of the Trocar is one-piece construction of steel, with a really nice, small, but stout tip.

The blades are all steel as well and they’re 0.035 inches thick, with a cutting diameter of 1-3/16 inches.

So, it provides a pretty decent size cut, just one 1/16 of an inch bigger than the standard 1-1/8 inch cut. This head is 100 grains.

Now, another thing about them is they have a 3-point blade retention system. The blades are held in place at three different points just to make sure that you don’t lose a blade, even on hard impacts.

They have a nylon washer at the bottom just to help secure them snuggly to your arrow.

-

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Angry Arrow™

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Black And Gold Dots

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® N-Tune™ Nock Tuning Reflective Arrow Wraps – Out For Blood™

$18.99 – $27.99 Select options This product has multiple variants. The options may be chosen on the product page

Performance tests

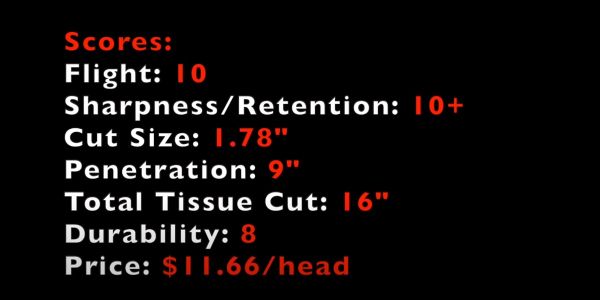

I was eager to put these to the test. I tested them for long range flight, edge sharpness, edge retention, for penetration, and durability.

As always, in these tests, I used my Bowtech SR6 set at 72 pounds. I used Bishop Archery FOC King Arrows in 460 grains.

All right. Let’s see how the Muzzy Trocar performs.

Long-range flight

the Muzzy Trocars flew great at 70 yards. I was able to pop a balloon with no problem.

Out of the box sharpness test

In the out-of the box sharpness test, the Trocar was able to cut paper after five strokes of an arrow shaft. And, I will add that by the way they cut the paper, they are some of the sharpest blades that I’ve ever tested.

-

N1 Outdoors® Stain The Vanes™ Bowhunting Tee

$24.99 – $30.99 Select options This product has multiple variants. The options may be chosen on the product page -

N1 Outdoors® Just Pass’N Through™ Bowhunting Tee

$24.99 – $28.99 Select options This product has multiple variants. The options may be chosen on the product page -

Sale!

N1 Outdoors® N1 Moments™ Licking Branch Buck SS Tee

$5.00 Select options This product has multiple variants. The options may be chosen on the product page

Ballistic Gel Penetration Test

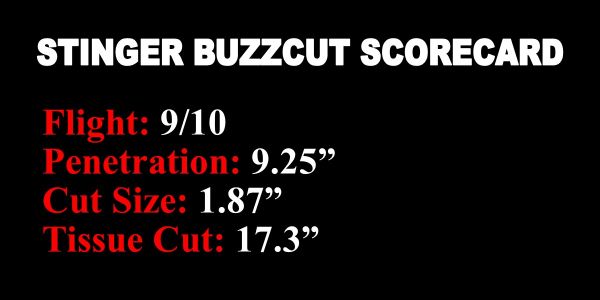

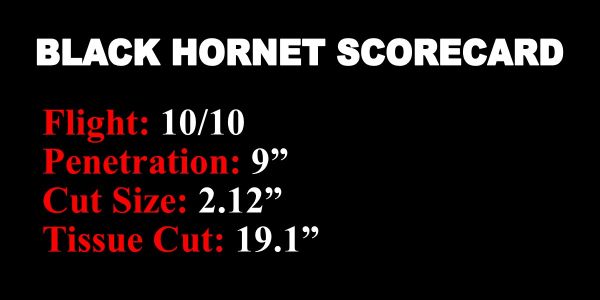

I shot the Muzzy Trocar through ballistic gel to test penetration. The Trocar penetrated 9 inches, which is pretty impressive penetration. See picture below.

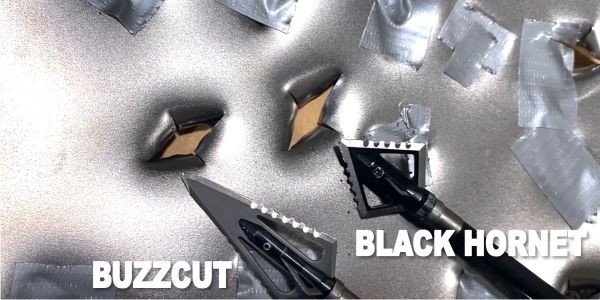

Steel plate test

In the steel plate test, I shot the Muzzy Trocar through .22 gauge steel plate five times.

As for the holes themselves, you can see below that it really does make three “slits” rather than three big triangles.

You get a little bit of an extra curl because of the offset blades, but it’s not the most impressive wound channel compared to some others like the Exodus broadheads. (That one opens up much more of a triangular hole than it does three slits). But, in terms of durability, the Trocar did very well.

Muzzy Trocar broadheads review | Final Thoughts

So what do you think of the Muzzy Trocar?

I’ve got to say, it’s a performer.

I know this head has been around for awhile, and it can easily be overlooked by many, with all of the new heads that are coming out. But, this head definitely has a lot going for it.

This is a pretty stout head.

It flew fantastic. It penetrated really well, made a nice wound channel, and held up pretty well.

So, check out the scorecard below and see how it compares to other similar heads like this and see if it’s the right head for you on your next deer hunt.